Efenco, a Tallinn-based deeptech become cleantech startup, has raised €4.5 million to further develop its “fire on turbocharge” technology.

The capital provided is a combination of €1.3 million led by Ivo Remmelg for EstBAN Syndicate and €3.2 million in grant funding from the European Innovation Council and Estonia’s Archimedes Foundation.

1.5° degrees

While governments, industries, and consumers are collectively keeping an eye on that crucial 1.5° figure and accelerating efforts to reduce if not eliminate carbon emissions, the truth of the matter is that fossil fuels are still very much in need in a number of industries.

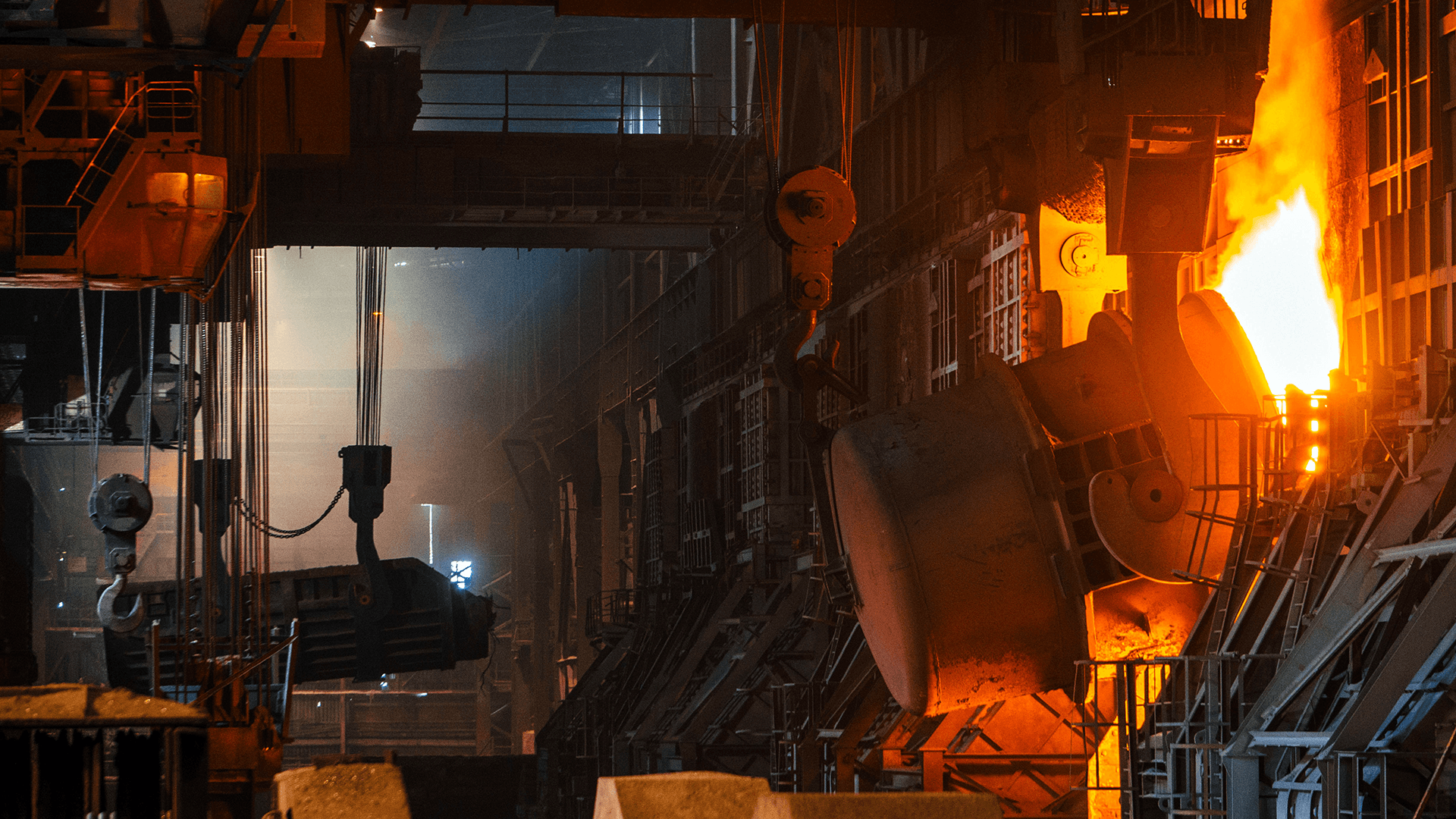

Take for example a core industrial material such as steel. The traditional method of producing steel involves the smelting of raw iron and carbon at temperatures approaching 1,600° C. These temperatures are achieved via the burning of, you guessed it, fossil fuels.

In so much, the steel industry alone accounts for 11 percent of the global emissions of carbon dioxide and around 7 percent of the global greenhouse gas emissions.

While fuels such as renewable hydrogen are beginning to become viable, fossil fuels still account for nearly 80 percent of global energy production at over 140,000 TWh.

Cold plasma

Where Efenco steps into the picture is not through offering a new renewable, but by dramatically increasing the efficiency of existing technology. Using cold-plasma assisted combustion technology, Efenco says that its solution can (eventually) improve the combustion efficiency of natural gas by up to 40 percent and of hydrogen by up to 75 percent.

Unlike other plasma-assisted combustion tech, found in jet engines, for example, Efenco’s cold-plasma approach does not require an external energy source, rather, recycling the heat generated by combustion to create plasma and enhance the efficiency of the reaction.

The company’s flagship product, the high-energy ray ceramic chip (HERC), reduces CO² emissions and fuel costs by at least 18 percent in energy-intensive industries such as electricity generation, steel manufacturing, pulp and paper manufacturing, ceramics and cement production, and district heating.

The company calculates that its initial technology could be installed in 30 percent of all gas boilers being used in the EU at present for high-temperature industrial process heat applications. This 18 percent efficiency gain represents a potential 5 percent total reduction in the EU’s energy consumption and carbon emissions from natural gas combustion — a greater potential savings than from solar and wind combined, or nuclear.

Residential. Eventually

While currently applied to large-scale boilers, according to Efenco, smaller-scale boilers, such as those found in domestic heating solutions are on the company’s roadmap.

The company has six commercial partnership deals inked including those with Finland’s Adven, Estonia’s Thermory, and Bepco.

Lead image: Photo by Ant Rozetsky

Would you like to write the first comment?

Login to post comments