Humanoid robotics is well and truly coasting the innovation hype wave with abundant funding and high expectations. In the past year, European humanoid-focused companies have attracted high-profile investments — from Germany’s Neura Robotics, which raised €120 million in Series B, to Norway’s 1X Technologies and its $100 million Series B aimed at developing household humanoid assistants like NEO.

Simultaneously, the European Commission under Horizon Europe is backing these developments, signalling that humanoids are seen not just as novelties but as strategic technology.

Yet one roboticist has a less prosaic view.

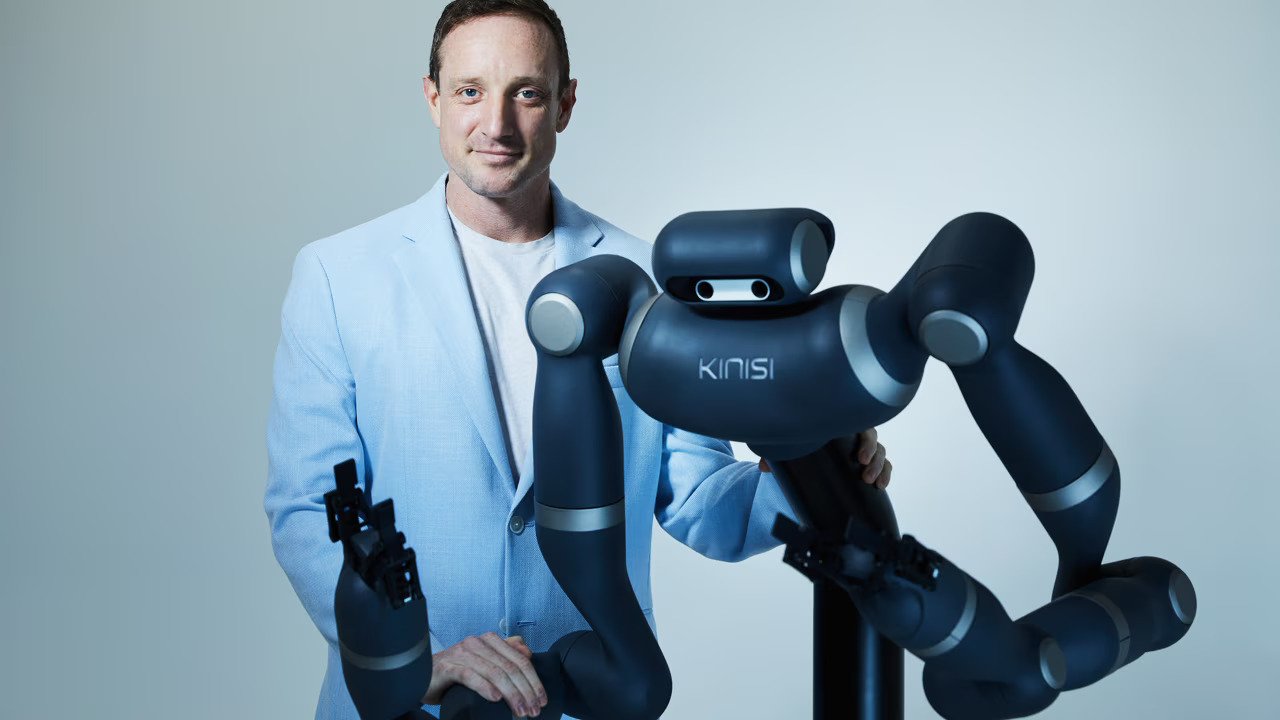

Kinisi Robotics founder and CEO Bren Pierce has a notable track record in robotics, previously launching ventures like Robotize and Bear Robotics, with over 10,000 robots deployed globally and more than $180 million raised from investors, including SoftBank.

Pierce admits he has been obsessed with robotics all of his life:

“Professionally, it’s been 20 years — the first 10 in academia, focused on humanoid robotics, leg actuators, locomotion. Over the last decade, I’ve founded several robotics companies. The most successful was Bear Robotics.

“We grew to 200–300 people, shipped over 25,000 robots, and LG acquired a 50 per cent stake.”

Staying legless

According to Pierce, there’s definitely a humanoid bubble, where VCs are rushing to invest in bipedal humanoid robots – “even though more immediately available humanoid bots will be a better fit for enterprises for the foreseeable future.”

“Many of the robots you see today look identical to what I worked on 10 years ago at DLR in Germany, or even like Honda’s Asimo from 20 years ago. The hype today is really about new AI models, not the form factor.”

Even as self-obsessed humanoid robotics obsessive, he thinks they’re humping the gun:

“Want your robot to fall over, break down, and cost a fortune? Build it with legs. It’s already hard enough to bring an AI model to market — why overcomplicate it with legs or five-finger hands?

Customers don’t necessarily want that. In our conversations with warehouse and factory operators, they see humanoids with legs and hands as cool toys, not industrial tools that can run 24/7.”

Kinisi is designing a robot that’s closer to a cobot on wheels — a mobile base with an arm — powered by foundational AI models. The company focuses on the software layer rather than trying to reinvent both the hardware and the AI at the same time.

“Commercialising multiple brand-new technologies together is extremely difficult.”

Kinisi Robotics bets on practical, wheeled humanoids for industry

Kinisi Robotics is a UK-US startup that builds practical, wheeled-base humanoids for warehouse automation.

Founded in 2024, Kinisi’s flagship model, the Kinisi 01 (KR1), was developed in just six months and is designed as a wheeled-base humanoid robot built to handle repetitive, physically demanding tasks across industries.

Its compact wheeled design allows for stable, agile navigation on warehouse floors, sidestepping the complexity and maintenance demands of legged robots.

KR1 combines strength and precision, capable of handling payloads up to 10 kg while also performing delicate manipulations with fine motor control. Importantly, the robot can operate for up to eight hours on a single charge, with swappable batteries and self-docking capabilities enabling minimal downtime.

Its onboard AI processes data locally, ensuring rapid, reliable operation without depending on cloud connectivity. Its not self-learning but rather demonstration-based — employees can guide the robot through a task once, and KR1 will replicate it without the need for coding. A fleet-wide shared knowledge system means operational insights are distributed among all units, enabling collective improvement over time.

Initially targeted at warehouse logistics tasks such as picking, placing, and transporting goods, KR1 is also being positioned for future roles in retail stocking, light manufacturing, and maintenance, all without requiring significant infrastructure changes.

“We don’t sell science fiction”

Pierce asserts:

“At Kinisi, we don't sell science fiction. We build robots that actually get work done. By equipping practical, wheeled-base humanoids with the latest LLM intelligence, we make them adaptable to any problem in any warehouse.

Unlike wobbly bipeds, our bots are smart, speedy, scalable, and safe to work alongside humans so we can solve today's labour shortages.“

Show ponies offer dazzle rather than substance

Pierce is critical of the promise of many humanoid robotics on the market compared to their real performance in the wild. Many videos showcase humanoids performing impressive stunts — flips, parkour, and cooking in pristine kitchens. But according to Pierce, these aren’t realistic indicators of capability:

“These are usually staged demos in ideal environments — spotless kitchens, brightly coloured single objects on clear backgrounds. In the real world, conditions are messier. Warehouses are flat, so legs aren’t necessary. Why spend on 14 motors when two will do?”

In terms of industrial customers, Pierce contends that “no warehouse is asking for a robot that can do backflips. They’re asking for one that shows up to work.”

Further, he notes that in some humanoid projects, you see two separate teams — one working on AI models, the other just trying to get the robot to walk. “Very few have demonstrated a fully integrated model where the robot can walk, navigate, and manipulate objects in one flow.”

Serving the 70 per cent

Most of Kinisi’s customers need robots for repetitive, physically demanding jobs: unloading pallets of metal parts, moving heavy boxes, and transferring items to conveyor belts. In warehouses, it might be walking back and forth, picking and placing boxes.

Pierce contends, “Historically, automating these tasks would cost millions. Now, with AI, you can train a robot to do 80 per cent of the work quickly, and people can focus on higher-value tasks.” Unlike behemoths like Amazon and Ocado,

He explained that about 70 per cent of warehouses are small, irregular spaces with mixed inventory.

“They can’t justify huge automation budgets. Our robots are attractive here because they don’t require cages, can be serviced quickly, and people can step in instantly if there’s an issue, avoiding the need for costly backup lines or large amounts of buffer stock.”

Kinisi has a working prototype in pilot trials with factories and warehouses.

“Our north star is running an entire eight-hour shift and fully replacing a human in that role. If you can’t match 100 per cent of the job, customers won’t buy.”

Pierce asserts that while there’s plenty of public interest in robotics in the home, “B2C rarely works out commercially. Most people won’t spend thousands on a device to do simple chores. Businesses, on the other hand, will invest for productivity, reduced injury risk, and staffing flexibility.”

Pierce likens the humanoid hype to the early car industry. “People wanted a “faster horse.” Now, people seem fixated on anthropomorphic robots, even if there are more efficient designs. Specialist or semi-specialist form factors will often be cheaper and more effective in B2B.”

The winners in robotics will be those that ship near-term solutions with drastically reduced price points.

What does AI bring to robotics?

Popping the hype bubble I wanted to understand what real benefit AI offers to robotics. According to Pierce, its generalisability and speed of deployment.

“Many of the tasks our robots do could have been done before with classical programming, but it would have taken a team of 5 to10 engineers several months to program them.

With AI and imitation learning, you can train in simulation and deploy in days with one or two engineers. That opens up automation for smaller, previously unviable jobs.”

Past robotics booms offer a cautionary tale for today’s humanoid hype

Humanoid robotics are far from the first wave of robotics hype.

In 2019, I wrote about the collapse of several well-funded consumer robot companies. In the preceding two years, we saw the demise of Anki Robotics—maker of Cozmo and Vector—after raising $182.5 million; Jibo, which raised $72 million; and Mayfield Robotics, the $73 million-backed maker of Kuri. Both Jibo and Kuri sought to redefine the home companion robot market but shuttered quickly.

Jibo offered limited practical utility, while Kuri failed to justify its premium price against far cheaper smart speakers.

Pepper, produced from 2014 until mid-2021 with around 27,000 units sold, was discontinued due to weak demand. Following its maker, Aldebaran Robotics (formerly SoftBank Robotics Europe), entering receivership in mid-2025, Pepper is now definitively out of stock, with little prospect for future development or support. Many of these early consumer robots were essentially “iPads on wheels” and were quickly outpaced by the rapid improvement of voice-controlled assistants like Alexa and the growing capabilities of smartphones.

Today, functional home robots such as Roomba vacuum cleaners cost under $500 (with numerous budget imitators), and specialised robots are available to wash floors, mow lawns, and clean windows—offering far more value and utility for the average household.

Pierce stresses that in robotics, the focus should be on solving real problems in environments where automation delivers tangible ROI.

“Flashy demos might raise funding, but lasting value comes from tools that work reliably in the field.”

Would you like to write the first comment?

Login to post comments