Global food waste continues to be a huge problem. According to figures from The World Counts, roughly one-third (1.3 billion tons) of food is wasted annually. And it's not just food leftovers that go to waste in our homes and restaurants; it occurs before the food even gets to our homes.

Senoptica Technologies is a sensor technology and analytics company that uses optical sensors created by their patented food-safe ink to determine the oxygen level inside packaged foods, offering manufacturers and retailers real-time insights into the condition of goods inside, predicting spoilage before it happens.

The company was founded In 2018 by Brendan Rice, Dr Steve Comby, and Dr Rachel Evans (who developed the initial sensor concept) as a spin-out company from Trinity College Dublin.

This week, it announced that the US Food and Drug Administration (FDA) had approved its entry into the North American market.

I spoke to Brendan Rice to learn more.

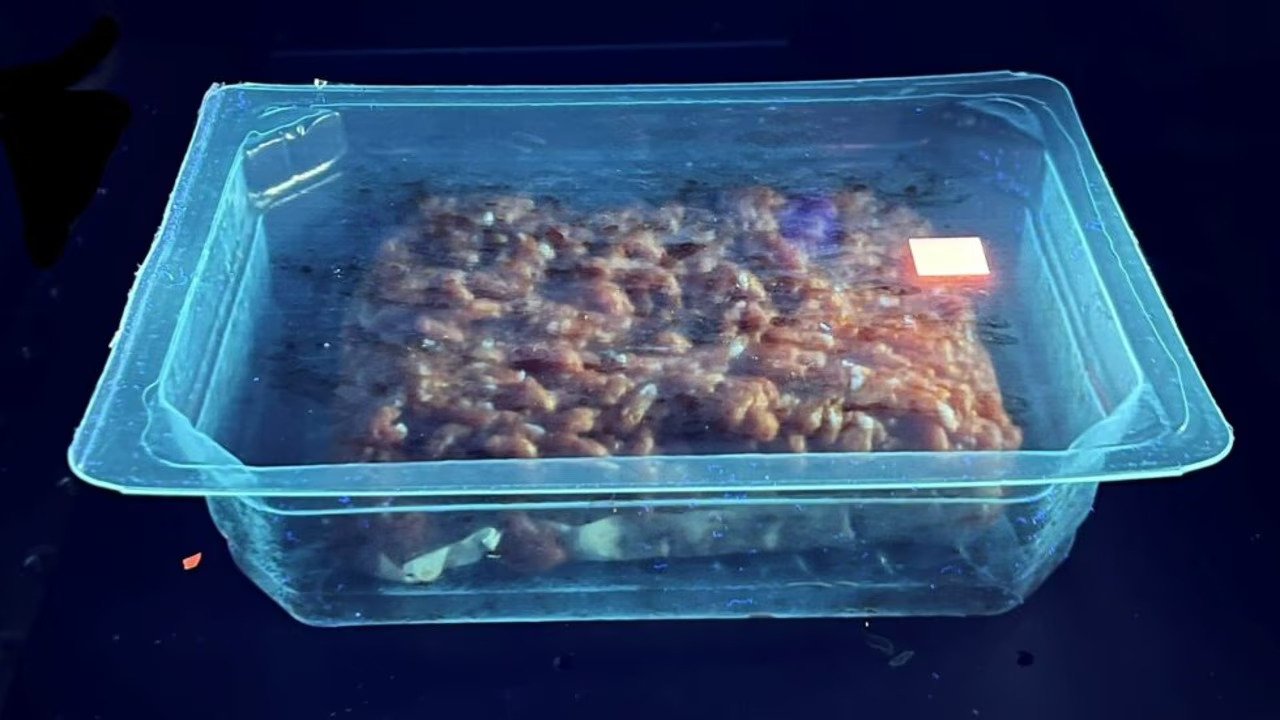

The company is focused on food that is sold in modified atmosphere packaging, which accounts for half of the world's fresh packaged food, from bagged salad to sliced cooked meat, cheese, some fruits and bread.

Modified atmosphere packaging (MAP) is a food packaging technology that extends the shelf life of perishable foods by altering the gas composition inside the package.

Regular air contains about 21 per cent oxygen, which can cause spoilage in many foods. MAP reduces the amount of oxygen and replaces it with a mixture of gases, typically nitrogen, carbon dioxide, and sometimes carbon monoxide. This extends the shelf life of püeroshable food and reduces the need for preservatives.

However, if the package leaks or is not sealed correctly in the first instance, the modified atmosphere can be compromised, and the food can spoil more quickly.

How does Senoptica's tech work?

Each pack has an optical oxygen sensor based on a patented food-safe ink printed inside the film covering the pack.

In food manufacturing, as the pack approaches the end-of-line inspection system, it goes through a leak accelerator. This device helps accelerate seal and packaging defects and slow leakers.

In supermarkets and retail stores, an inline scanning system reads the sensor output and determines whether a pack should be rejected. This scanning system can be easily incorporated into existing packing lines. As a result, out-of-spec packs can be rejected, and the food can be repacked.

Furthermore, using a handheld scanner, the sensor can be read at any point in the supply chain, from the cold store to the supermarket shelf, allowing spot checks of the pack gas levels to be carried out.

Rice explains:

"We provide new information that will allow them to move the product quicker and benefit the consumer. There's nothing wrong with the food; the packaging has let it down."

In the future, Senoptica's tech could also send a signal to the retailer's systems, allowing them to print out a ticket that says, "Use this today."

For manufacturers, this means defective food packs can immediately be returned to the packing line and repacked, saving time and money across the entire food value chain. This saves time and money for retailers and consumers and could effectively mean the end of best-before dates.

Rice explains that currently, the food industry is only able to do a tiny number of sample tests of all the packs it produces—about 0.03 per cent of all the packs that it produces—because the tests that exist in there are destructive, meaning once a pack has been tested, you have to repack the product and throw away the packaging.

"Our technology can test every pack."

Senoptica has increased the chances of finding a failed product by 11,000 times, so failed packs are unlikely to get out into the supply chain in the first instance.

In early pilots, the startup also simulated a supermarket. Rice was guiding a trolly and knocked over food.

He explained:

"I right-sided the packages, all of which looked fine, but found that the fall had impacted their gas levels, reducing their lifespan."

The company recently conducted UK supermarket trials, which found that about 5 per cent of packs on the shelf had already failed because the atmosphere designed to keep the food fresh wasn't there.

"This means the retailer will end up throwing it away. They'll lose revenue and margins, and they'll have to pay to dispose of it."

This pilot trial was the first time that anybody's ever been able to see what's going on inside the food pack at the scale we've done over a long period of time.

But it's also sharing really deep insights into how we can help prevent food waste by looking at opportunities to extend the product's shelf life so we can see what's happening over time without disrupting the pack."

The company has gained valuable traction in a sector with rising inflation and narrow margins. Rice explained:

"Global retail is a very, very competitive market. We see the opportunity here for them because the margins are significant, the technology works, and it provides economic value and helps them with their sustainability drive."

Based on its FDA approval, Senoptica is set to expand operations in the UK and retail trials of its technology across the United States. The company hopes to reduce food waste by 11 million tonnes annually, the equivalent of 240 million tonnes of CO2.

Would you like to write the first comment?

Login to post comments