I attended the Sixth Sense Summit earlier this year, where I encountered some really interesting IoT tech that offers great promise for commercial IoT applications.

Slovakian company RVmagnetics is a deep tech startup customising unique measurement solutions based on proprietary MicroWire sensors.

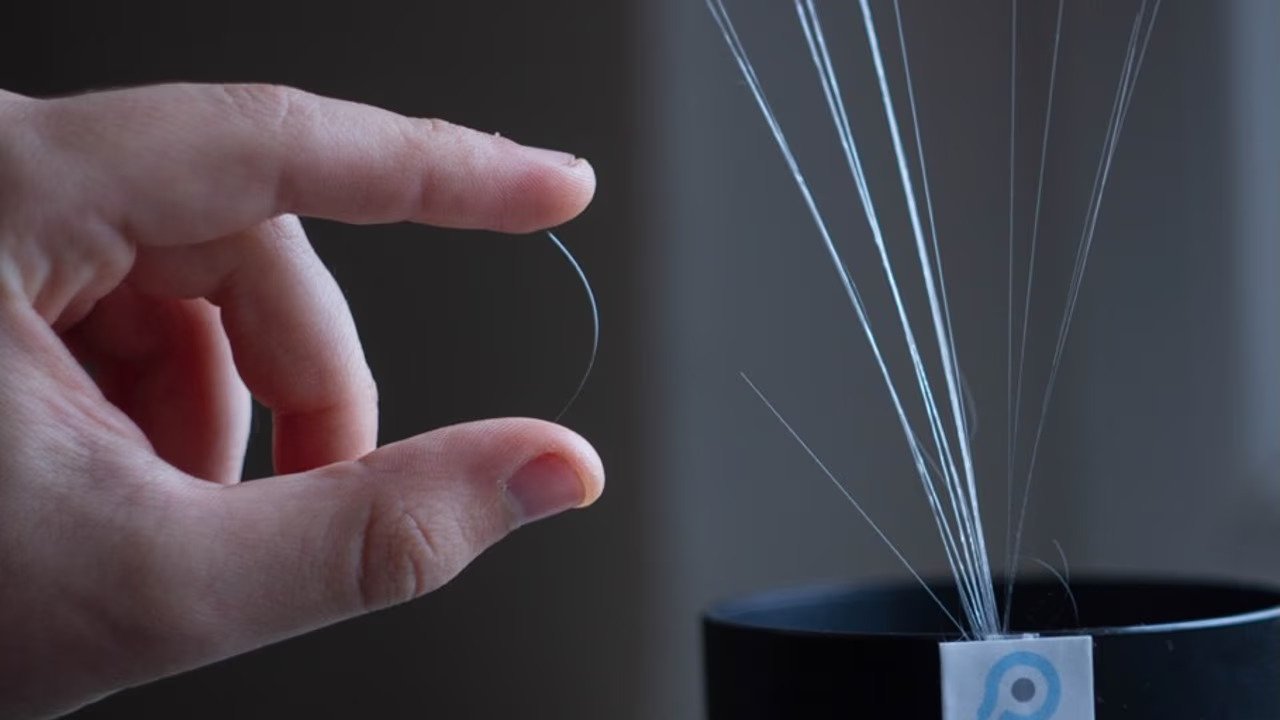

MicroWires are biocompatible sensors, about the width of a human hair (diameter ca. 20–70 µm) and measure a range of physical properties without contact.

These are the smallest passive sensors in the world and they pack a powerful punch.

The tiny MicroWire sensors are compact, robust, and contactless devices.

They utilise magnetic fields to transmit real-time data on various physical quantities. They can collect physical data from spaces that are not visible or audio-detectable with accuracy, and within timescales not otherwise possible.

The sensors are made with a glass coating, which makes them integrable in harsh environments.

I spoke to Tigran Hovhannisyan, account manager at RVmagnetics, to find out more.

He explained that the company was the brainchild of Professor Rastislav Varga, an expert in magnetism in condensed matter with 25 years of research experience in basic and applied magnetism.”

“Professor Varga is always happy to say, ‘We have a lot of solutions for a lot of problems that we don’t know exist.’”

The sensor can provide measurements of pressure, temperature, magnetic field, vibrations, positions, and more.

“You can receive contactless information through the magnetic field, which makes it applicable across a range of use cases such as healthcare, engineering, structural health monitoring and transportation. MicroWire sensors replace the need for high power consumption.

They enable non-destructive testing and structural health monitoring without altering the properties of the materials they are embedded in.

Further, signals can be transmitted even through different materials, including metal, composite materials, concrete, human tissue, and wood, at distances of up to 10 centimetres. Multiple sensors can feed into a single reader for a streamlined user experience.”

MicroWires are sustainable and efficient – a gram of material makes a kilometre of wire! RVmagnetics manufactures them in-house in Slovakia.

“We can make about 100,000 sensors within 10 minutes.” details Hovhannisyan.

Why industry-specific incubators make sense

Sixth Sense is a program offered by the Manufacturing Intelligence division of Hexagon to help innovative companies with brilliant ideas who are looking to bring their products to broader markets and scale their business with the help of Hexagon.

Hexagon identifies challenges and asks companies to submit applications to describe their products and services and how they address those challenges.

The most innovative proposals are invited to pitch to Hexagon's panel of experts. Around ten are chosen for an intensive innovate-on-the-job scaling program, which will deliver a concrete project supported by coaching, workshops, and connections to Hexagon customers.

Tigran Hovhannisyan, spoke highly of the Sixth Sense program, explaining it “allowed us to find and talk to the right people.”

"These people and this accelerated program specifically provide us with an opportunity to find the specific problems that only we can solve. And once we solve it, a whole new market is unlocked.”

The company is engaged in R&D and developing partnerships to bring MicroWire sensors to mass production and target high-potential applications. It plans to roll out its tech to commercial customers later this year.

Lead image: RVmagnetics. Photo: uncredited.

Would you like to write the first comment?

Login to post comments