Oxford University spinout company Alloyed, a developer and manufacturer of advanced metallic components for aerospace and electronics, has raised £37 million Series B funding.

The company is focused on automated design and manufacturing through additive manufacturing, or industrial-scale 3D printing, which combines many functions into one metal part.

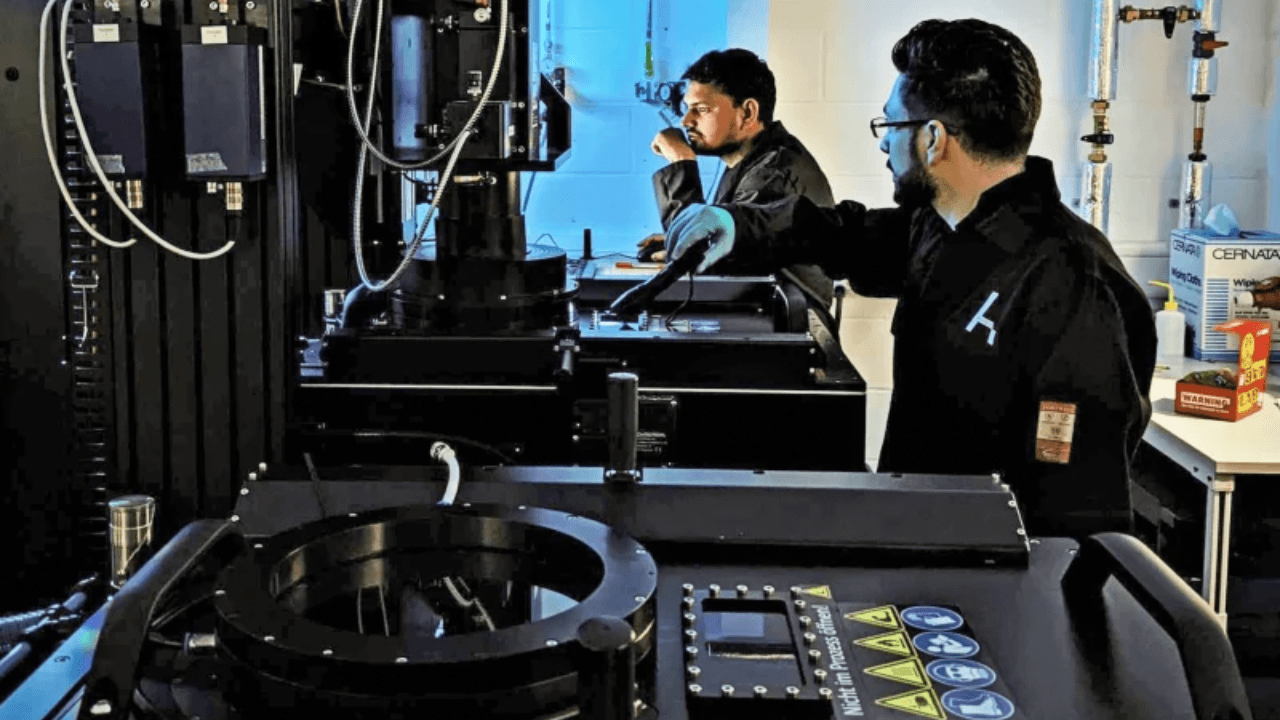

Alloyed’s UK base in Abingdon is already home to one of the largest fleets of Additive Manufacturing machines in Europe.

High-performance metallic alloys will have a significant role to play in future industries and the energy transition, as companies seek to deploy ever stronger and lighter metals to meet the demands of next-generation technologies.

Its current customers include Boeing, Microsoft, Anglo American and BMW, with its applications spanning a wide range of industries – including lightweight antennas and structural components for satellites, high-temperature-resistant alloys for jet engines, as well as precision parts for jewellery, wearables such as virtual reality headsets, and smartwatches.

Japanese investors SPARX and the Development Bank of Japan, led the round, with participation from Aviva Investors and Future Industry Ventures (a Redstone and SBI fund).

Michael Holmes, CEO of Alloyed, said:

“After 5,000 years, metal remains the material of choice for the toughest jobs, and our mission is to harness our digital platforms to make metal components lighter, stronger, and more precise, all while reducing costs and maximising sustainability.

Automated design and manufacturing is an industry where the UK, with our expertise in materials science and world-class engineering capability, has the potential to lead on the global stage and Alloyed is at the forefront of this transformation.”

Takaki Demichi, Director and Head of Investment for Next-Generation Growth Division at SPARX Asset Management, said:

“Additive manufacture has great promise for the energy transition and future products across a range of industries, but has been held back by a range of engineering challenges which we believe are directly addressed by Alloyed’s materials, processing, design, and production technologies and its highly data-driven approach.”

Yuki Takemori, General Manager of Innovation Promotion Office at Development Bank of Japan, shared:

“Japan has a well-established ecosystem of small and medium-sized manufacturing enterprises in alloy production and our collaboration with Alloyed will enhance the sector even further.

With this new partnership, we will create a model case for commercialising technology - cultivated in one of the world’s leading academic institutions.”

The fundraise will be used to expand Alloyed’s manufacturing facilities in Abingdon, UK, and Seattle, USA, as well as accelerate the development of its digital platforms for the design and processing of improved alloys and alloy components.

Lead image: Alloyed. Photo: uncredited.

Would you like to write the first comment?

Login to post comments