enaDyne, a startup specialising in fully electric, non-thermal plasma catalysis for sustainable chemical production, has raised €7 million in seed funding. The round was co-led by Amadeus APEX Technology Fund (a collaboration between Amadeus Capital Partners and APEX Ventures) and Energy Capital Ventures, with participation from Antares Ventures, Possible Ventures, and returning business angels Wolfram Drescher, Andreas Werne, and Sven Sieber.

Founded in 2021 by Philipp Hahn, Christian Koch, Martin Drößiger, and Torsten Lorenz, enaDyne brings together expertise in plasma physics, catalysis, engineering, and materials science.

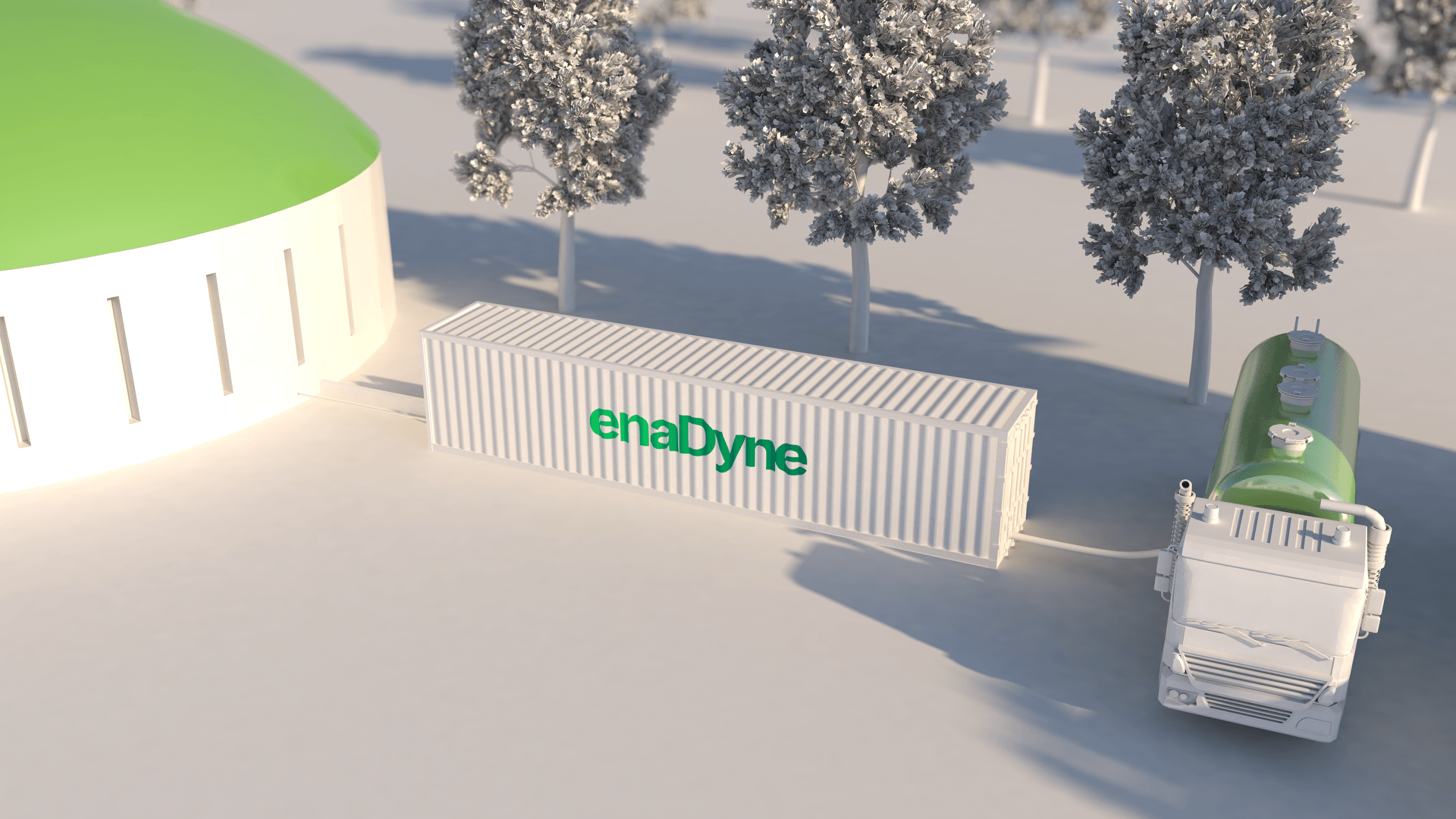

The company has developed a reactor technology that converts CO₂ and other process gases into chemicals such as syngas, methanol, and ethylene. Its modular, containerised systems can also reduce hard-to-abate emissions, including CF₄ and PFAS, providing a more sustainable option than conventional production routes.

By integrating proprietary electrodes with plasma-active catalysts, enaDyne enables on-site, scalable production that reduces both process emissions and persistent pollutants, offering a practical pathway to decarbonise chemical manufacturing. Current results show CO₂ conversion rates above 70% with competitive selectivities, while the modular architecture supports rapid deployment and scaling across industrial applications.

According to co-founder and CEO Philipp Hahn, the company’s approach reimagines chemistry itself:

We can switch our reactors on and off like a light switch, deploy them anywhere renewable energy exists, and serve both conventional syntheses and the valorisation of waste CO₂, producing the exact chemicals our customers need. This funding gives us the resources to prove that sustainable chemistry isn’t just possible—it’s inevitable and profitable.

The fresh capital will be used to build and deploy a 20-foot modular pilot plant at an industrial customer site by mid-2026, develop the first commercial product for plasma-based PFAS abatement, and establish a scalable production value chain.

Looking ahead, enaDyne’s long-term ambition is to become the global platform for non-thermal plasma-based chemical synthesis, with the goal of deploying tens of thousands of containerised units by 2050.

Would you like to write the first comment?

Login to post comments