Paris-based deeptech Hummink has raised €15 million to expand the deployment of its patented High-Precision Capillary Printing (HPCaP) technology, which enables manufacturers to print metals and functional materials with high accuracy and address microscopic defects in real time.

The round was co-led by KBC Focus Fund, Cap Horn, and Bpifrance, with follow-on support from Elaia Partners, Sensinnovat, and Beeyond, and additional participation from the French Tech Seed fund managed by Bpifrance as part of France 2030 and the European Innovation Council Fund.

As microelectronics support the growth of artificial intelligence and high-performance computing, small manufacturing defects have become increasingly costly. Imperfections at the sub-micron scale can compromise entire batches of chips or displays.

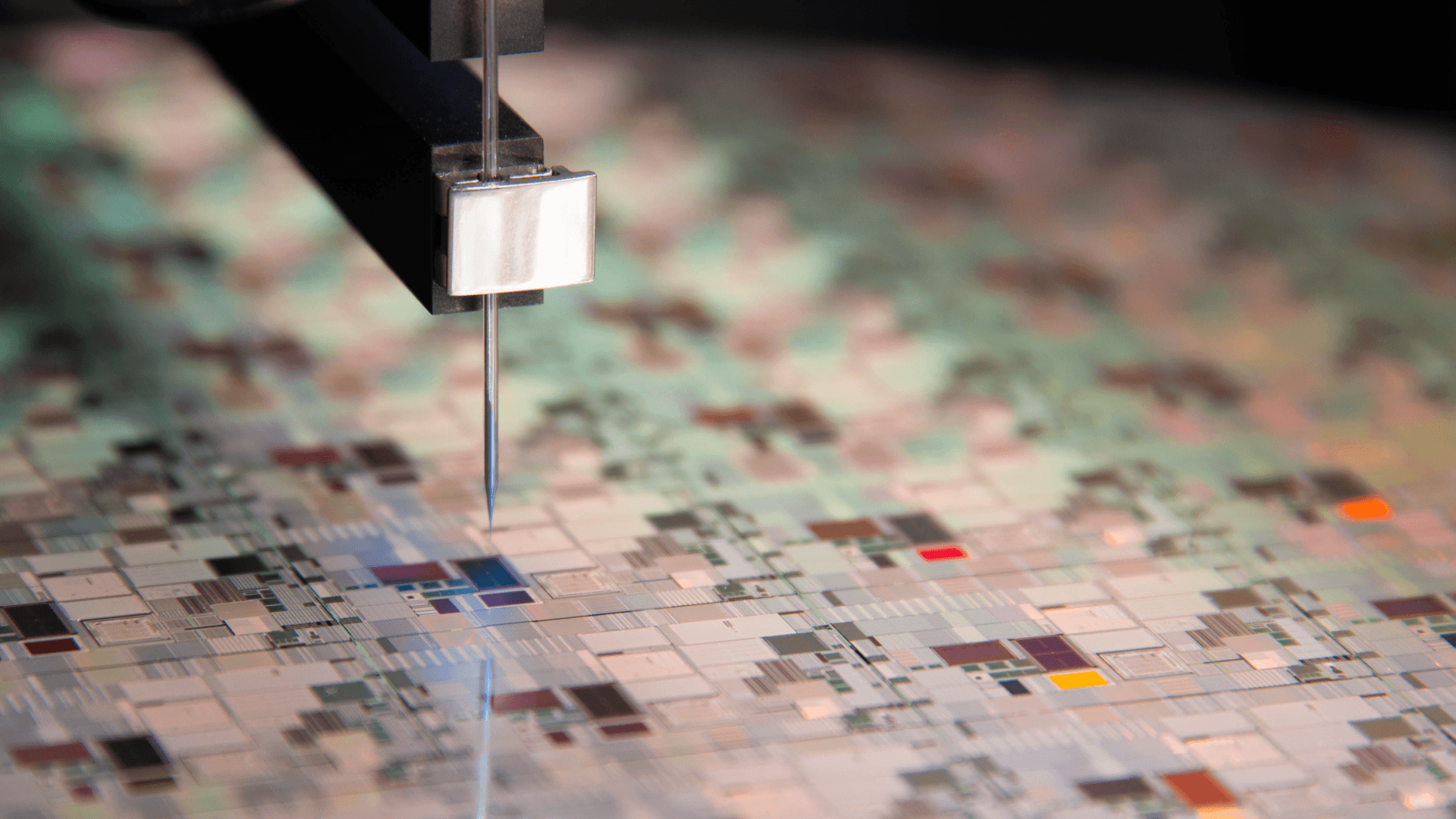

Founded in 2020 as a spin-off from École Normale Supérieure - PSL and CNRS, Paris-based deeptech company Hummink focuses on this challenge. Co-founded by materials scientist Amin M’Barki and hardware startup operator Pascal Boncenne, the company has developed a technology that operates like a miniature fountain pen, depositing material at the nanoscale in a controlled manner. This process enables manufacturers to create and adjust circuitry directly at the sub-micron level, with applications in semiconductor packaging, next-generation memory, and advanced displays.

While traditional lithography remains central to electronics manufacturing, it still produces defects that contribute to yield loss and material waste. Hummink’s printing tools are designed to complement lithography by detecting and correcting such defects at the micronic level, with the aim of increasing output, reducing scrap, and lowering environmental impact.

Hummink’s initial integration focus is on next-generation OLED displays for smartphones and laptops, where up to 30 per cent of annual production is reportedly discarded due to microscopic defects, equating to an estimated €16 billion in losses and significant material waste. The company’s technology is designed to correct many of these defects, enabling manufacturers to recover output that would otherwise be scrapped.

Our mission is to bring precision where it has never been possible before. Microelectronics is at the heart of the AI revolution, and every micron matters,

said Amin M’Barki, Co-founder and CEO of Hummink.

Hummink currently generates revenue by selling its NAZCA demonstrator, a first-generation high-precision printing system for R&D labs, along with custom conductive inks. NAZCA is already installed in labs and research centres across Europe, Asia, and the United States, including Duke University, where it was used to create fully recyclable, sub-micrometre printed electronics published in Nature Electronics.

The new funding will be used to further develop Hummink’s industrial printing module and prepare its technology for integration into semiconductor and display fabrication lines.

Would you like to write the first comment?

Login to post comments