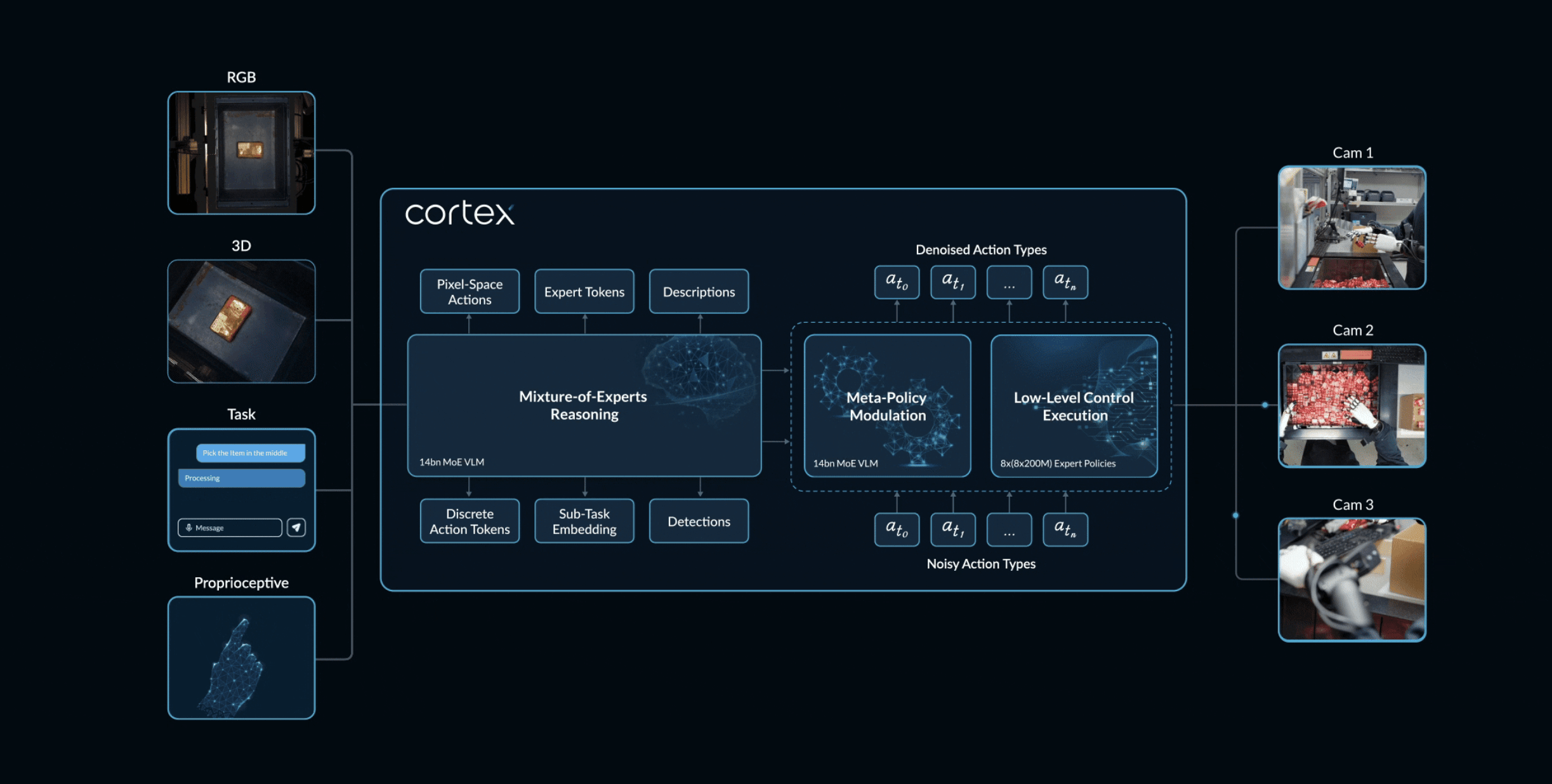

The robotics industry is undergoing a major transformation — moving away from rigid, task-specific programming toward systems that require general intelligence. Sereact is entering this new era with Cortex, a Vision-Language-Action (VLA) model that unifies perception, reasoning, and control within a single framework.

As embodied AI transitions from research labs to real-world industrial settings, Cortex demonstrates that foundation models can be deployed reliably across diverse robots and environments, delivering tangible economic and operational benefits at scale.

I spoke to the co-founder and CEO of Sereact, Ralf Gulde, to learn more.

Cortex aims to do for robots what GPT did for language

Significantly, the model isn’t just another robotic control system. It tries to do for robots what GPT did for language: unify perception (vision), reasoning (language), and control (actions) in one model.

The model has been trained on the largest real-world robotics dataset, aggregated from over 100 industrial deployments not just simulations, “which makes it far more robust than academic or lab-only models,” shared Gulde.

According to Gulde, this scale and diversity of training fuel its generalisation performance and enable robust zero-shot capabilities.

“Instead of relying on task-specific code or per-site retraining, Cortex formulates abstract task representations that can be projected into the operational space of any robot.

As a result, standard workflows such as picking or sorting can be executed within hours of deployment."

Further, instead of hardcoding tasks (like “pick up this exact part in this exact way”), it learns from demonstrations and generalises to new tasks without reprogramming. This is a big deal, because traditional robots are very rigid.

“You can say: 'Sort these items by colour', and the robot figures it out, which removes the need for programmers on the factory floor.”

Hardware-agnostic by design

Normally, in industrial robotics, each robot needs its own control logic, but not with Cortex, which is hardware-agnostic.

As a result, the same model works on robot arms, mobile manipulators, and humanoids without retraining. It generates abstract task expressions which are translated into robot-specific motion spaces at execution time.

“This allows integration across major industrial robot platforms and with both suction and finger grippers, requiring only minimal adaptation to existing automation infrastructure,” shared Gulde.

Self-healing and edge-case handling

Further, if an unexpected event occurs (e.g., transparent objects, deformable items, obstacles), the system can recover autonomously in real-time, rather than failing and requiring human intervention, which is particularly valuable in factories.

There’s also a fleet operation loop — each robot sends anonymised data back to improve the global model for industrial robots. This accelerates collective learning and continuous improvement.

Deployment in hours and not weeks

Today, integration and calibration often take weeks/months per facility. This is due to its architecture, which generalises from first principles rather than memorised patterns, leading to faster ROI and lower deployment costs.

In terms of impact, ROI is measured primarily through shorter deployment cycles, reduced integration effort, and lower error rates in picking and handling. Gulde explained that because Cortex does not require object-specific teach-in, customers avoid time-consuming setup and adaptation:

“Customers report measurable improvements in throughput stability and fewer manual interventions. Feedback consistently highlights rapid time-to-value and robustness in real production environments.”

Industrial robotics enters a new era

Cortex is already deployed in over 100 systems within Mercedes Trucks and BOL, successfully demonstrating zero-shot capabilities across various robotic platforms, including arms, mobile manipulators, and humanoids. At Daimler Truck, the challenge was to automate kitting processes involving a high diversity of objects, including complex geometries and reflective metal parts.

“Cortex enabled autonomous operation with both finger and suction grippers, selecting the most suitable gripper type for each object without object-specific teach-in,” shared Gulde.

At bol.com, the goal was to automate one of the most demanding areas of their fulfilment network.

According to Torsten Grüninger, Product Manager at Daimler Truck:

“With Sereact, we have found a solution that fully integrates both two-finger and suction grippers, enabling perfect gripper/product matching without the need for time-consuming object teach-in.

Sereact's advanced technology can handle objects accurately and operate completely autonomously without human intervention."

Cortex does not rely on template-based recognition. Instead, it fuses multimodal sensory input with reasoning to infer object affordances and select suitable actions. What does this mean in practice?

Gulde explained that by leveraging knowledge from hundreds of millions of real-world manipulations across 100+ deployments, the model achieves strong generalisation capabilities that transfer to new, unseen scenarios. This solves a very real-world practice at BOL.

Hugo Driesse, Process Engineer at BOL, explained that the company deliberately placed Sereact’s robot “in one of the most complex parts of our operation, with the toughest integrations and handling requirements.”

“What impressed us most is that it can handle our full range of more than 500,000 SKUs without cherry-picking. And working with the Sereact team has been excellent, they respond immediately and actively think with us about every step of the integration.”

In terms of scaling, Gulde believes that in the future, the most effective way to scale is through strong partnerships. In 2025, Sereact announced collaborations with tier-1 system integrators such as AWL, Hörmann, Reesink, Kardex, and Körber, enabling Cortex to be deployed within large-scale projects through established channels.

However he asserts:

“The key technical challenge lies in ensuring robustness across heterogeneous environments and hardware platforms, while the main business challenge is delivering reliable global support and efficient rollouts across regions.”

Sereact is a testament to Europe’s strong industrial robotics ecosystem. By adding a real-world-trained AI layer that generalises across robots and tasks, Sereact demonstrates that Europe can not only participate but lead in embodied AI.

As part of its next steps, Sereact aims to scale Cortex across thousands of robots and Lens instances, working closely with its system integration partners. The company is extending deployments to new geographies, including North America, and advancing the model architecture with stronger reasoning, memory, and planning capabilities.

Looking further ahead, future optimisations will move Cortex’s decision-making processes closer to brain-like cognition, with predictive control, working memory, and meta-cognitive modulation.

Lead image: Sereact. Photo; uncredited.

Would you like to write the first comment?

Login to post comments