Hyperdrives is a Munich-based deep-tech startup building the next generation of high-performance electric drives — and proving that you don't need venture capital to achieve commercial traction.

Founded in 2021, it moved fast, went to market, and attracted commercial customers just by bootstrapping, creating motor-cooling tech that fills a critical customer need and is scalable across the whole mobility vertical.

I spoke to CEO Robin Renz to find out more.

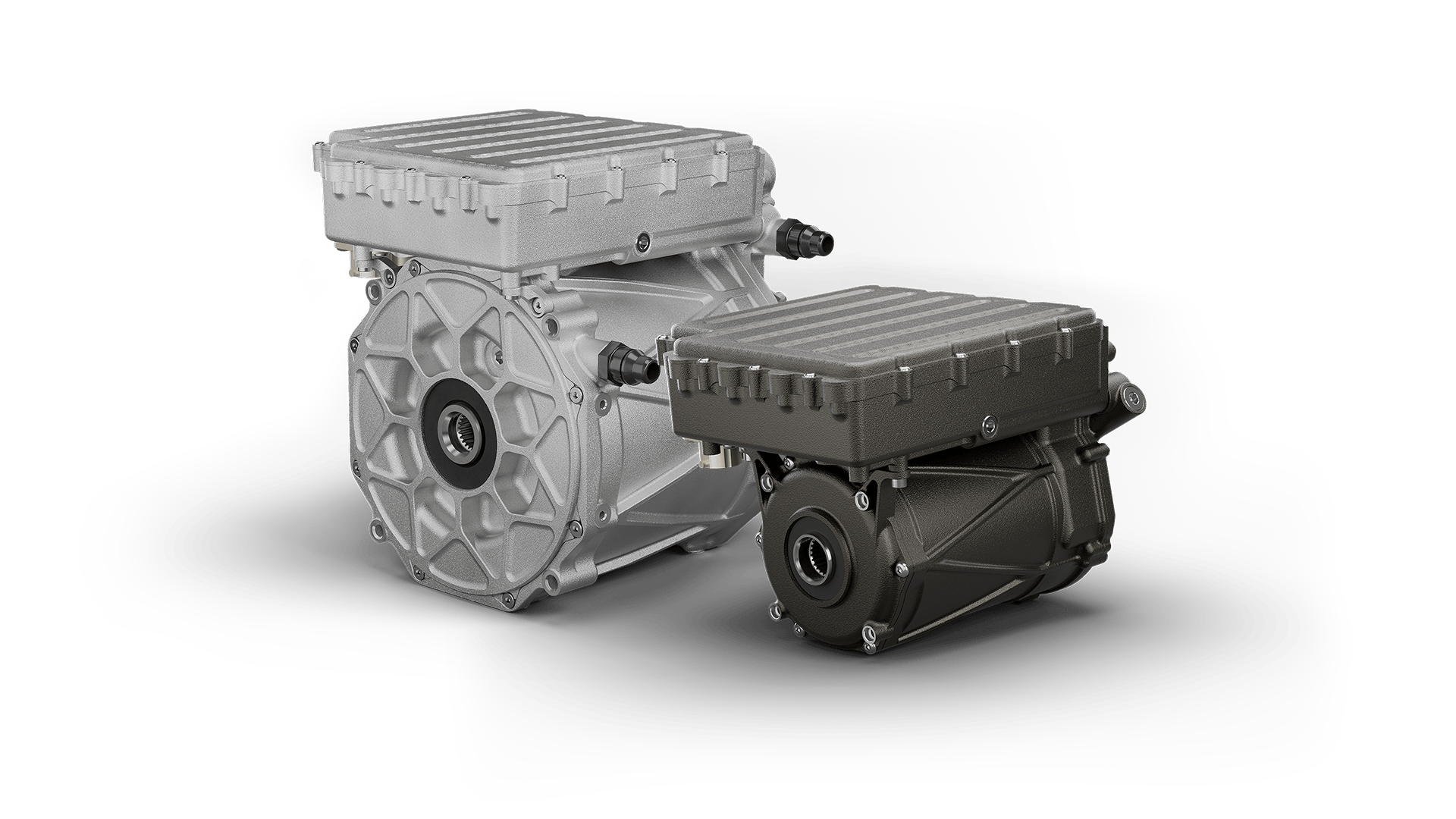

The deeptech breakthrough powering the future of electric drives

The ongoing electrification of transport demands electric drives that are more powerful, efficient, and cost-effective at scale. Conventional motors cool indirectly via water jackets or oil spray, which leaves temperature hot spots in the windings, limits current capability, and compromises efficiency.

Hyperdrives' breakthrough lies in making direct hollow-conductor cooling viable for mass production using standard materials and existing automotive production lines.

Previous attempts at this approach were complex, expensive, and prone to reliability issues. Hyperdrives has solved these challenges with a technology that channels coolant directly through hollow copper conductors — cooling the motor at the precise point of heat generation.

This eliminates thermal bottlenecks and achieves a tenfold improvement in heat dissipation: a 100 K temperature difference in a conventional motor corresponds to just 10 K in Hyperdrives' system.

Because the copper runs cooler, the motor can safely handle much higher current densities, delivering over 12 kW/kg continuous power density at the system level — roughly twice that of a conventional EV motor of the same size. The result is a motor that's lighter, smaller, and up to 10 per cent more efficient over real-world drive cycles, offering a unique performance-to-cost advantage across automotive, aerospace, and marine applications.

According to Renz:

"We build electric motors and full drive systems — the motor plus the inverter, which is essentially the brain managing electricity from the battery or fuel cell.

What sets Hyperdrives apart is our power density — extreme power in a very small package. We achieve this not with exotic materials or 3D-printed windings, but by re-engineering the cooling."

Every electric motor has a thermal limit. The more current you feed into the windings, the hotter it gets. Conventional cooling is "like boiling an egg and then putting it in cold water — it cools the outside, but stays hot inside."

Hyperdrives does it differently: its coolant runs through the copper conductor itself.

"That gives us ten times better heat transfer. We can push more electricity through the motor without overheating — that's how we reach our power density. It sounds simple, but making it compact enough for a car and industrialising it for mass production is incredibly complex. That's where much of our IP lies — in the industrialisation process itself," explained Renz.

From balcony prototype to breakthrough

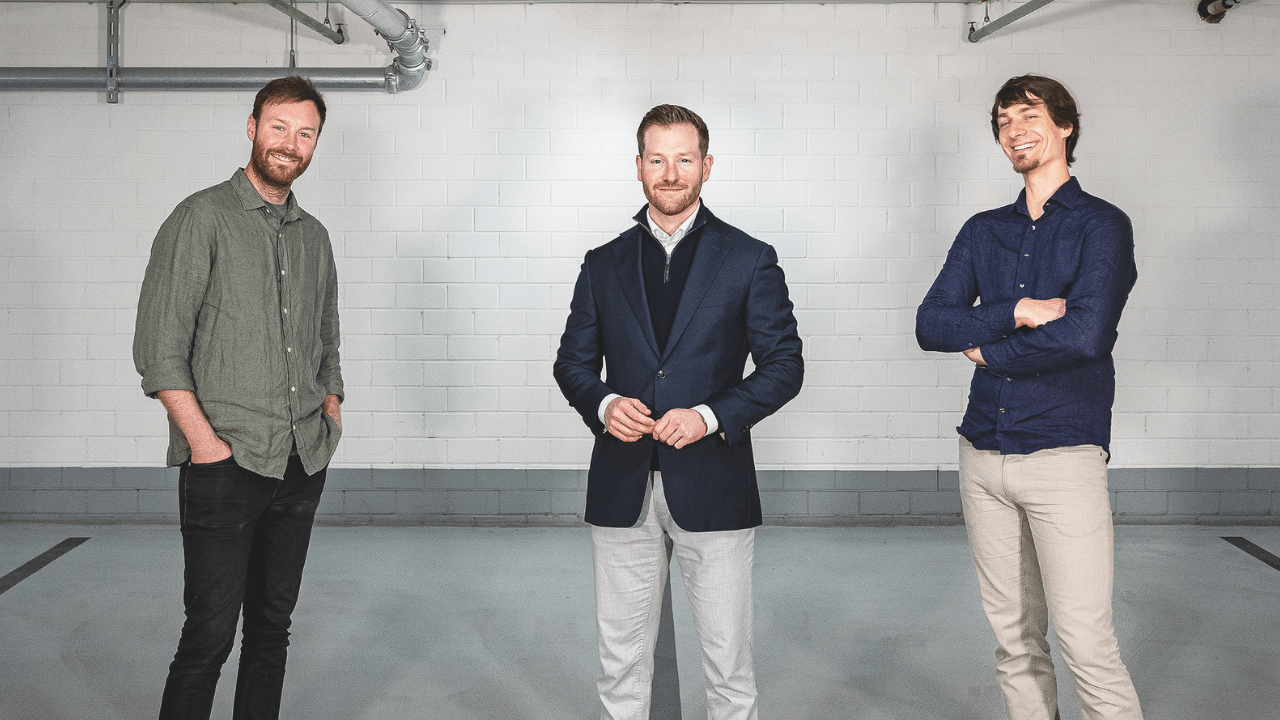

Hyperdrives was founded by a team of seasoned automotive innovators:

Michael Numberger, a pioneering engineer and former lead designer of Le Mans – winning hybrid electric drive systems with over 13 years of experience; Robin Renz, an experienced strategist and M&A professional who helped pioneer Volkswagen Group's MEB electric platform; and Benjamin Hengstler, a motor software and controls specialist who previously led the development of a Formula E–winning electric drive system.

At some point, Numberger discovered the technology that defines hyperdrives today — hollow-conductor cooling. He realised he could achieve motorsport-level power density at a fraction of the cost and complexity using this method.

He wanted to develop it internally but wasn't allowed to, so he quit his job. He and Hengstler built the first prototype in his kitchen and on his balcony.

When it was ready, they tested it at the University of the Armed Forces in Munich because it was powerful and they needed a proper test bench.

Hilariously, the test was so successful that all the cables melted and the fire alarms went off —

"The bench couldn't handle the power the motor produced, recalled Renz. "That was the moment they realised it worked, not just on paper but in hardware."

Renz joined later — he knew Numberger from university. They were looking for a commercial co-founder, and that's how we teamed up.

One scalable, adaptable cooling system to power them all

Significantly, Hyperdrives doesn't build a single motor for a specific application. Rather, it has a technology that can be applied to many different electric motors, from cars, trucks, and boats to industrial tools and aircraft, as well as agricultural use cases.

Renz detailed:

"We don't change the fundamental principle or design of an electric motor either, which really helps with industrialisation and production — the architecture itself stays the same.

It's a bit like with a turbocharger: you take a normal V6 motor, put a turbocharger on it, and suddenly it performs like a Ferrari V12. It's similar to us — obviously very different physics — but the same idea."

Commercial interest before investment

Hyperdrives stands out because the startup manufactured products for commercial customers without investor funding.

Renz admits, "Bootstrapping made us slower in some ways. Still, it meant we skipped at least one financing round and built real traction before raising capital."

"We bootstrapped for three years — and when I say bootstrapped, I really mean it. We lived off our savings, and there was no grandmother investing money into it. We financed everything ourselves through early customer revenue."

The team of four reached about a million in revenue last year, a mighty feat for a hardware startup."

However, the beginning of this year, Hyperdrives raised its first round of funding.

"We already have a pretty broad commercial pipeline, and to convert that, we needed to do our homework," explained Renz.

"We needed it because we're now doing more expensive things like system testing and automotive testing, which require significant capital, and we needed to extend the team to handle that."

The response from mobility OEMs is enthusiastic because, according to Renz, everyone in high-power motor R&D is trying to solve the same problem: how to push thermal limits.

"We're doing what many call the 'holy grail of cooling.' Everyone knows it's the right direction, but no one else has figured out how to make it manufacturable."

So, when the team talks to OEMs, they immediately understand the benefits. The main question is about durability and scalability — can it survive mass production? That's what it's proving right now.

Hyperdrives' first customer was a hypercar manufacturer building a hypercar platform. The second was a company that builds electric hydrofoiling boats, which had previously used extremely high-powered Formula E motors, which are extremely expensive.

"Our hypercar customer actually connected us with them — they said, 'You need to talk to these guys,'" shared Renz.

At that time, they were still a home-office company.

"The marine company decided to give it a shot, and since then, we've been their motor supplier. One thing led to another — a bit of luck and a lot of hustle."

How Hyperdrives balances custom projects and mass production

Hyperdrives has two business pillars.

The first is a low-to mid-volume project business. Renz explained:

"A customer comes to us with a specific application — for example, an electric boat or drone.

We take our technology platform, adapt it to their needs, manufacture it with a partner in Germany, and deliver the hardware.

We plan to scale that to hundreds or low thousands of units per year over the next two years."

The second pillar is the high-volume automotive business, where Hyperdrives licenses its technology so OEMs can integrate it into their existing production lines. Significantly, Hyperdrives' processes can be seamlessly integrated into the existing automotive supply chain.

"In fact, we can keep about 80 per cent of their existing setup unchanged. We only replace two processes, one of which is currently dirty and expensive. That's crucial because no carmaker is going to scrap eight global production lines to adopt a new motor design," shared Renz.

Hyperdrives is currently expanding its ten-person team to fifteen by next year as it moves into its next growth phase. The company's priorities include securing a major project customer to scale its technology into the hundreds of units per year, launching its first pre-development project with an automotive partner, and establishing a pilot production plant in Munich.

According to Renz, the pilot plant will demonstrate the company's industrialisation processes in real hardware.

"It's crucial both to scale our project business and to prove to OEMs that our production process works — that it's high quality, efficient, and ready for automotive validation.

We want to get to the point where a production planner from BMW, for example, can stand next to our pilot line, stopwatch in hand, and see for themselves that it works."

Lead image: Hyperdrives' founders. Photo: uncredited.

Would you like to write the first comment?

Login to post comments