Traditional custom manufacturing is slow, opaque, and inefficient. Engineers and procurement teams often face long lead times, inconsistent quality, and a fragmented supplier network that requires time-consuming manual quoting and negotiation.

Critical parts may take weeks to source, innovation slows, and costs rise — all while visibility into supplier reliability and part quality remains limited.

Geomiq is transforming the industry with an AI-powered Manufacturing-as-a-Service (MaaS) platform that connects engineers, startups, and enterprise buyers with a global network of vetted manufacturing partners for custom part production.

The platform supports CNC machining, injection moulding, 3D printing, and sheet metal fabrication — helping customers move from prototype to production through a seamless online workflow from CAD upload to delivery, shortening traditional lead times and simplifying procurement.

I spoke to Sam Al-Mukhtar, CEO and co-founder of Geomiq, to learn more.

Built from first-hand frustration

Founded in 2017 and headquartered in London, Geomiq was born out of Al-Mukhtar’s own experience as a mechanical engineer struggling to source parts while bringing products to market.

He detailed:

“Everything used to be done manually — you’d email 3D models around, wait days or weeks for a supplier to respond, have back-and-forth calls, emails, all of it.

When we started Geomiq, we replicated that process in the background as we built out our automation systems.

Now, customers upload a 3D model to the platform, and we give them real-time design-for-manufacture feedback.”

According to Al-Mukhtar, CNC machines cost hundreds of thousands — even millions. And they require skill to operate. Most manufacturing is done overseas due to lower labour costs.

"Our platform identifies the best supplier for a job based on pricing, technical specs, and performance track record.”

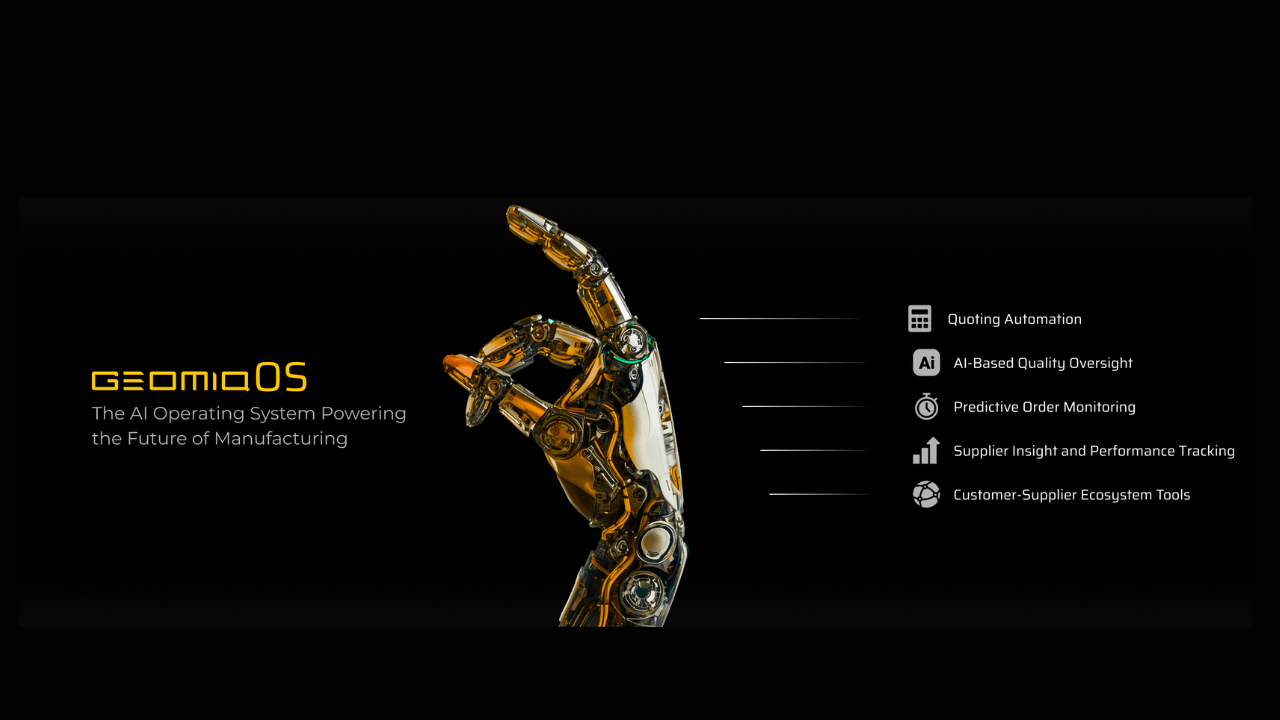

Introducing AI-powered GeomiqOS

Geomiq has recently launched GeomiqOS, a proprietary AI-powered operating system now running the company’s global production workflows.

Already live across its hubs in the UK, India, China, and Portugal, GeomiqOS is the backbone of how Geomiq manages quoting, quality, delivery risk, and supplier coordination at scale.

Built in-house, the system replaces manual oversight with a network of intelligent agents. It interprets CAD files, estimates pricing, evaluates manufacturability, and suggests DFM improvements — all within seconds.

Geomiq is building its own LLMs — its third hire was a physics student who started building its pricing model.

The company uses a machine learning model to predict pricing — instantly — based on geometry, specs, and materials.

According to Al-Mukhtar, the company has always utilised ML, but now it's layering in LLMs to assist with pricing, as it's so proprietary.

“We have nearly 500,000 CAD files and around 1.5 million supplier bids. That gives us unparalleled pricing intelligence.

We prototype with off-the-shelf LLMs, but when the performance isn’t there — or when we need control for security reasons (especially with defence clients) — we build in-house.”

If the customer proceeds, the platform predicts the lead time and subcontracts the work to the most suitable supplier.

"Our system selects them based on over 30 data points — things like: have they made this material before, using this method, and did they deliver on time?”

It inspects part images and drawings to detect quality issues before dispatch.

“We use AI to analyse photos for damage, verify finishes, and reduce subjectivity. It’s not glamorous, but it’s crucial for custom manufacturing.”

AI fed with real-world feedback

GeomiqOS also tracks delivery risk in real time, and flags issues long before they escalate, as well as supplier responsiveness and conversion data — “if a customer sees a price and buys, that’s a validation”

“That real-world feedback improves the model — and it’s data we couldn’t get from external LLMs.”

GeomiqOS gives its team and partners shared visibility, faster decision loops, and a more resilient way to run production. The platform also tracks how suppliers perform — including hit rates, lead times, and non-conformance trends — and feeds those insights back into sourcing decisions.

Customers can onboard their own suppliers into the system, with GeomiqOS providing the same level of risk and quality oversight.

The platform includes features like automatic redaction of sensitive CAD data and a language model that scans reports to identify recurring quality issues across orders.

On-demand service for critical industries

Geomiq’s customers include companies like Brompton Bicycles, BAE Systems, and others, in high-tech sectors like space and robotics, where time is money.

Al-Mukhtar detailed:

“Our platform gives them instant quotes, fast lead times, and zero friction. It also works well for companies where every engineer can upload their own parts — we’re ideal for decentralised teams without a central purchasing system.”

In some companies, internal procurement processes introduce additional delays due to rigid systems that fail to align with the fast-paced needs of R&D and product teams.

Frustrated by slow internal processes, some engineers in large organisations even max out their £500 corporate card limits to expedite part orders through Geomiq.

According to Al-Mukhtar, before COVID, many companies gave engineers purchasing autonomy, such as £5k or £10k limits. After COVID, everything became centralised and cost-controlled.

“During COVID, we became essential suppliers for medical devices. That vertical grew fast. We were already set up to manufacture anything made from metal or plastic — so we didn’t need to pivot, just scale.”

Today, a customer can go from upload to order with zero human interaction.

Making custom parts as easy as Amazon

The company wants to make engineering as easy to purchase as something on Amazon, even for startups and SMEs. Al-Mukhtar explained:

“Most startups either use us or a handful of known suppliers. However, they often default to us out of the box because we offer self-service.

Especially with younger generations, they don’t use email much. They want live chat, instant analysis, and no delays. That was part of our inspiration, to make engineering as easy to purchase as something on Amazon.”

Geomiq was, according to Al-Mukhtar, “one of the first companies where you could buy custom parts online with a credit card. That felt revolutionary at the time!”

Geomiq’s fastest turnaround is five business days, with the average a mere 12 days. Critical to scale is automation. “The smallest order we’ve handled is £70. The largest? £600,000.

Today, the company has offices in London, Portugal, India, and China, with over 75 staff members.

Geomiq has recently been recertified for ISO and ISO 13485 (for medical devices), which enhances quality and scalability. And now, with its infrastructure in place, Geomiq is now focusing on service levels, aiming to cut average lead times below 12 days and make pricing even more competitive.

"Our goal is to evolve beyond being a marketplace — we want to be the trusted operating system for custom parts. Upload, configure, order — done.”

Since going live, GeomiqOS has reduced quoting times for complex parts by 80 per cent, eliminated nearly a third of surprise delays, and decreased repeat quality issues by 40 per cent through improved detection and root cause analysis.

Upcoming additions to the system include a conversational AI Copilot for quoting and tracking, dynamic pricing based on live factory capacity, and autonomous job recovery that re-routes delayed parts to keep deliveries on track.

“This is a long-term bet,” said Al-Mukhtar.

“We’re treating AI not as a feature, but as the operating logic of our company. It’s how we’ll make low-volume manufacturing more predictable, transparent, and scalable.”

It's a mindset that permeates the entire company. At Geomiq, every department is expected to use AI — it’s even part of performance reviews. If you're not using AI in your role, you’ll be asked why not.

“We’ve launched more internal products in the past three months than in the previous year. AI has supercharged us.”

Would you like to write the first comment?

Login to post comments