Over the last few years, the fashion industry has committed to sustainability in response to high demands from customers and investors.

Many retailers have shifted from fast fashion to new business models like clothing for rent and second-hand markets.

Growth in materials innovation has exploded with companies on a mission to develop long-lasting clothing from sustainable materials and a commitment to greater efficiency on the factory floor.

Before you read further, check out Part 1 of this article!

Here are some great startups showing how it's done:

Smartex.ai (Portugal)

Founded in 2018, Smartex has developed hardware-enabled, machine-vision-driven software to detect textile defects in real-time. This automated identification process reduces textile waste, CO2 emissions, energy, water, and capital expenditure.

The textile and fashion industry is notorious when it comes to waste. Up to 15 percent of fabric intended for clothing ends up on the cutting room floor — creating more than 90 million tons of waste yearly.

In response, Smartex uses AI, and IoT combined tailored hardware, vision software & machine learning algorithms to identify defects in fabric manufacturing inside circular knitting machines using computer vision, and machine learning. The ability to stop machines reduces unnecessary waste and fabrics that would otherwise be destroyed.

Smartex raised $24.7 million in a Series A round in November 2022.

Bananatex (Switzerland)

Bananatex® is the world’s first durable, technical fabric made purely from the naturally grown Abacá banana plants. Cultivated in the Philippine highlands within a natural ecosystem of sustainable mixed agriculture and forestry, the plant is self-sufficient, requiring no pesticides, fertiliser or extra water.

As a result it contributes to reforestation in areas once eroded due to monocultural palm plantations, whilst enhancing its farmers' biodiversity and economic prosperity.

Arda (UK)

Arda turns waste barley grain from beer brewing into a leather alternative called New Grain™. The grain is most commonly burned, sent to landfill, anaerobically digested into gas, or fed to animals as cheap feed.

DyeRecycle (UK)

DyeRecycle is the first technology that tackles chemical circularity in the fashion industry. It has developed a non-destructive separation technology of textile waste components: fibres & dyes, allowing their independent recycling back to the supply chain.

The process selectively extracts dyes from waste fibres, and transfers the dyes to a new fabric. This eliminates the use of new dyes in the dyeing process while enabling more efficient fibre-to-fibre recycling by providing discoloured white fibre as a high-value uniform input for mechanical and chemical fibre recyclers.

The liquid used for the process is recycled and reused, making the process fully circular by design.

Every garment dyed with DyeRecycle uses 85% less chemicals, 66% less water and generates 75% less carbon emissions.

The Fabricant (The Netherlands)

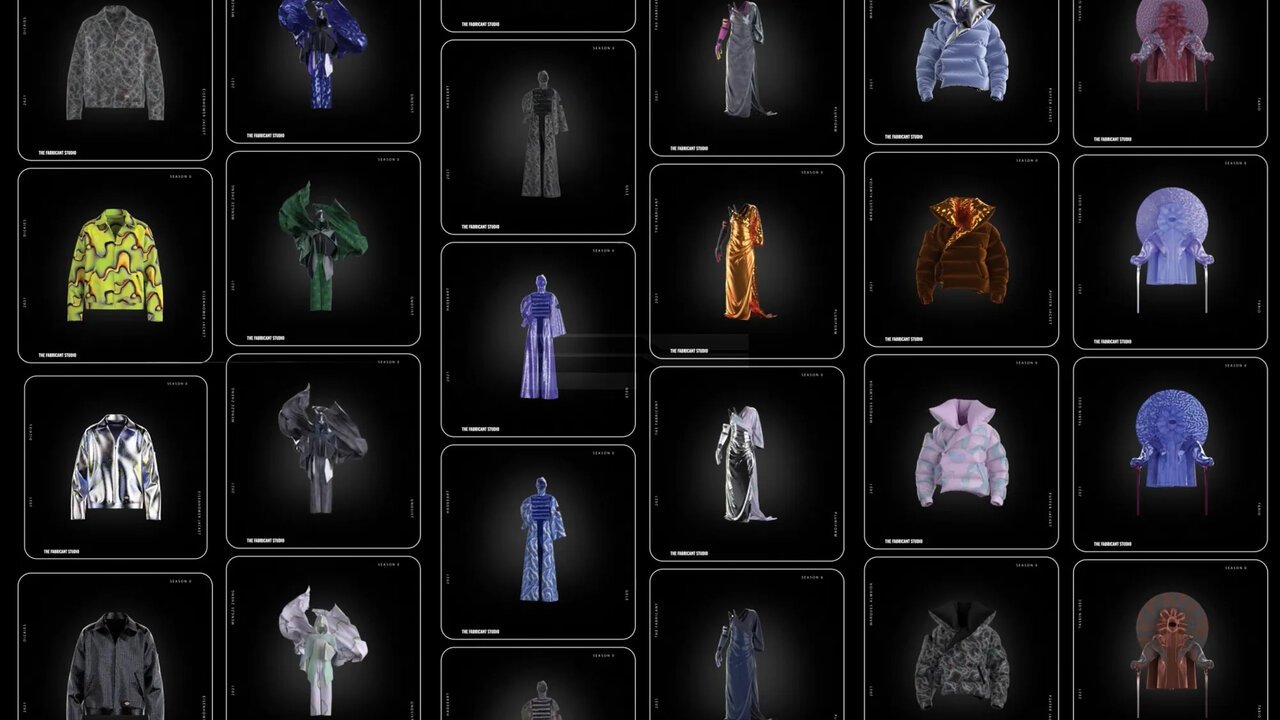

The Fabricant is a digital fashion house leading the fashion industry towards a new sector of digital-only clothing.

Brands can reduce their carbon footprint during the design and development stages by 30% if they use digital samples rather than physical ones.

Digital try-ons also minimise brand returns (in turn reducing the transporting and processing of unwanted goods.

The company has developed a platform where people can create unique NFT fashion items with a curated collection from a wide array of brands, creators, and designers. New fashion seasons are hosted where these designers and brands release raw materials for creators to mint, wear or trade their garments. Participants can also organise their own labels in return for tokens.

Lizee (France)

Re-commerce business Lizee makes circularity easy for big fashion retailers, having developed the necessary software to establish rent and reuse services for their wares.

The team then handles the picking, packing, shipping and facilitation of payments for rented products, oversees quality checks for returned products, refurbishing, and more.

The company has raised €9.3 million, most recently raising €7 million in Series A funding in January this year.

Would you like to write the first comment?

Login to post comments