Led by former OpenAI technical lead Jones Schneider, Karlsruhe-based Daedalus has today confirmed raising $21 million in a Series A funding round.

According to the company, the NGP Capital-led investment will be used to further develop Daedalus’ Manufacturing AI platform alongside scaling the company’s production facilities in Germany.

Perhaps not unlike a number of industries in flux at the moment, the manufacturing vertical seems to be at a crossroads. On one hand, we have news of startups such as SQCDP finding a market fit when it comes to dragging factory floor data out of the paper and pen era, while on the other, we have Daedalus.

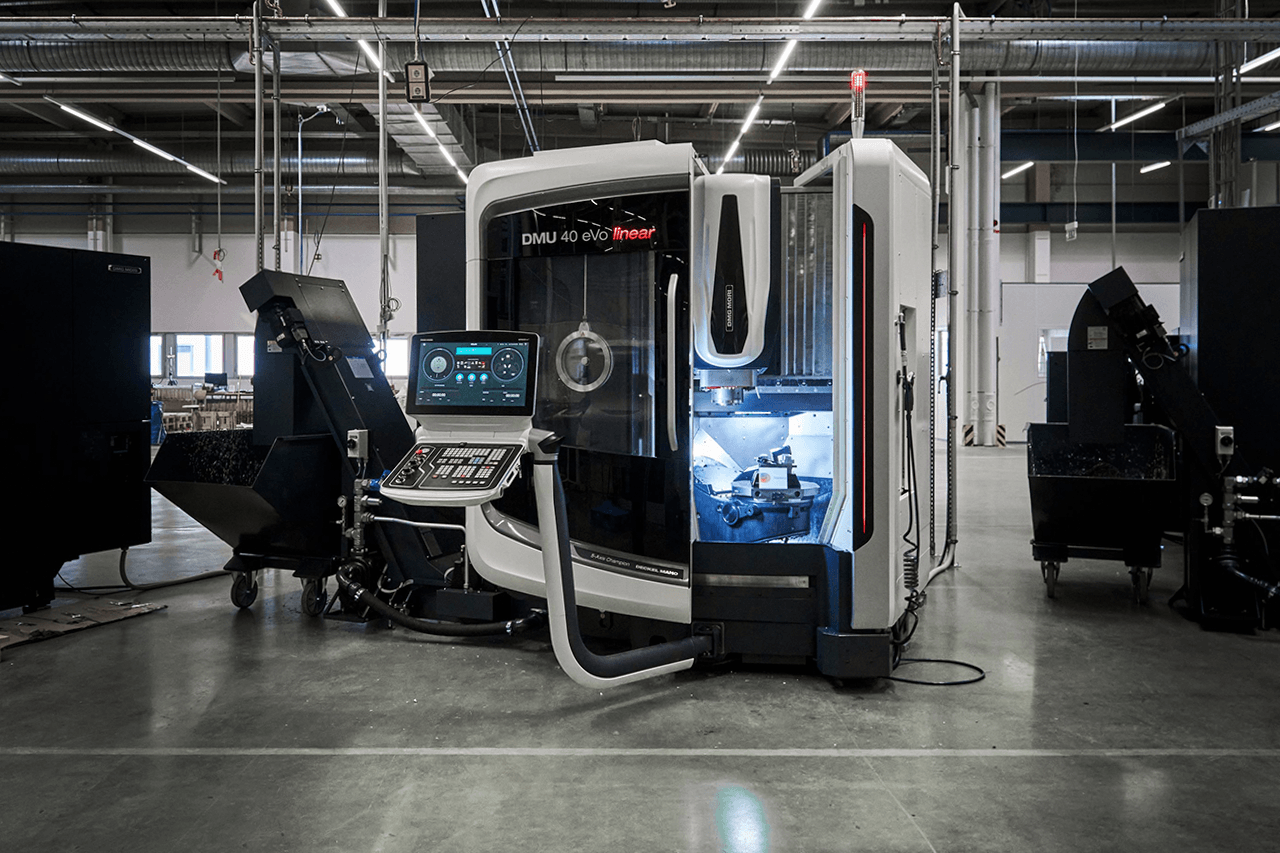

Self-billed as “Europe’s most modern contract manufacturer”, Daedalus is taking on centuries-old practices involved in manufacturing products and goods and not only automating them practically from end-to-end but making them instantly reconfigurable.

Driven headlong by AI, Daedalus’ offer can automate the entire manufacturing process beginning with quotes and see operations right on through to delivery for high precision and high-mix parts.

With milling, turning, and surfacing capabilities conjoined with a wide range of available materials and quality control measures thanks to optical coordinate measuring machine technologies, Daedalus offers sectors including semiconductors, energy, mobility, and pharmaceuticals the ability to source and deliver products reliably and at scale.

Daedalus founder and CEO Jonas Schneider elaborates:

"Imagine factories that possess the collective knowledge and expertise of all engineers and machinists who have ever worked in them, and can produce the most challenging parts with superhuman reliability and 10x efficiency.

“Daedalus is already making that vision real by revolutionising how we build everything from microchips to critical medical components — unleashing the potential of numerous industries with our AI-powered factories that forge bespoke parts on demand.”

If you think that Daedalus can be seen as a scapegoat/punching bag for the “but AI will take our jobs” thread, bear in mind that despite operating in a market that sees upwards of $500 billion in turnover per year, when it comes to precision parts, the majority of global firms operate on the whim of a highly fragmented supplier industry.

With many shops often staffed by 10 individuals or less, numbers that are sure to diminish in the face of an ever-worsening labour shortage in terms of machinists and artisanal production processes, the case can be made that while Daedalus might be a contributor to the problem, they’re also making headwind into finding the solution.

Scheider, who was the first engineer hired at OpenAI, and co-founded and led software engineering for OpenAI's robotics team, further explains:

"The conversations we have with our customers paint a shocking picture of the state of precision manufacturing. Our software-driven factory has already alleviated some major pain points, but we are still only beginning our journey.

“While we have already outscaled more than 50,000 incumbents, there is still $100 billion in annual demand we have not yet touched in Germany alone, and we're seeing demand from our existing customers exceed our capacity several times over.

“At the same time, we see many software features we can build to improve customer experience and internal efficiency further.”

In addition to NGP Capital’s lead, Daedalus’ Series A drew support from existing investors Addition and Khosla Ventures.

Lead image via Daedalus.

Would you like to write the first comment?

Login to post comments