French deeptech startup and specialist in silica aerogel Keey Aerogel, has raised €18 million Series A.

Founded in 2015 by Francisco Ruiz, Keey Aerogel produces silica aerogel from construction waste using carbon dioxide and ethanol recycled in a closed-loop process, making it the only “green” aerogel on the market.

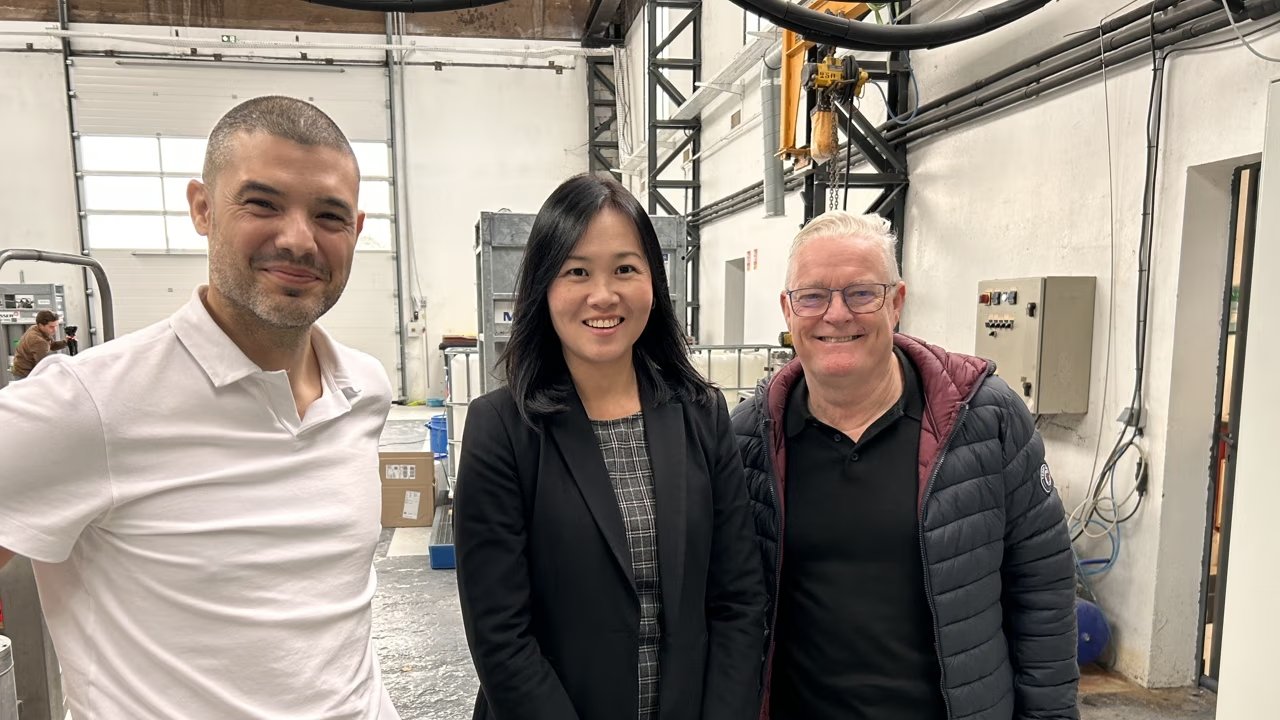

I spoke to Francisco Ruiz and Mike O'Connor, Keey Aerogels, sales director, to learn more.

Traditionally produced primarily in the United States and Asia (often with export restrictions), conventional aerogel is both expensive and polluting.

According to Ruiz:

“Today, the majority of aerogels are produced by a handful of American and Asian manufacturers using a synthetic derivative of silica, designed for specific industrial applications, at very high prices.”

Further, conventional aerogel relies on a precise synthesis process involving various solvents (carbon dioxide (CO₂), ethanol, among others), which are typically discarded after use, causing environmental harm.

Keey Aerogel has developed a patented solution for developing aerogel.

Ruiz detailed:

“We extract silica from construction waste or any waste containing sufficient silica, allowing us to produce aerogels more efficiently and at a reduced cost.”

Made up of 98 per cent air and 2 per cent silica —- one of the most abundant materials on Earth —- Keey aerogel is an ultra-high-performance thermal insulator.

Almost as light as air, it comes in various forms: powder, granules, or integrated into thin and flexible materials. Valued for its low density, porosity, and remarkable insulating properties - whether thermal, acoustic, or fireproof, it has numerous applications in construction, industry, and aerospace.

Keey Aerogel's fire-resistant material boosts EV battery safety

In the first instance, Keey Aerogel is focused on electric vehicle batteries, with a powerful impact on their thermal runway — where one battery catches fire, and the fire spreads to adjacent cells. This process which can occur in milliseconds.

Keey Aerogel can delay the burn, increasing the opportunity for a critical response and increasing overall safety.

Ruiz detailed:

“Our product prevents this spread for 5 to 10 minutes, giving passengers enough time to safely exit the vehicle in the example of a battery fire in a vehicle.

This requires a material capable of withstanding temperatures of up to 1,000°C while keeping adjacent areas below 100°C within.”

These materials are now entering the scale-up phase, and with the company focusing directly on collaboration with battery manufacturers in this industry.”

Europe’s first green aerogel

Keey Aerogel is able to offer a circular model to its clients, by using their waste to produce the raw material they can integrate into their products with a continuous, more efficient, and sustainable production method that incorporates closed-loop recycling of every solvent used.

Its next goal is establishing a second production facility as a stepping stone toward building a network of local factories close to end users. “

The ultimate goal is to build local factories capable of producing green aerogel from local waste to meet demand in short supply chains, thereby accelerating the energy transition,” explains Francisco Ruiz.

According to O’Connor:

"We keep everything local. Before reaching full localisation, we ensure it makes economic sense for our clients.

For example, if waste materials are treated onsite, it eliminates the cost associated with removing and transporting them elsewhere.

While this doesn't directly benefit us, it results in a significant cost advantage for our clients, making the solution very appealing."

Keey Aerogel’s pilot plant in Alsace, inaugurated in 2022 after seven years of research and development and the granting of three patents, was made possible thanks to early investments from Capital Grand Est and Innovation Fund during an initial €1.5 million funding round.

Currently in its pre-industrial phase, Keey Aerogel supplies aerogel to major European clients specializing in the construction sector. This second funding round, co-led by Bpifrance’s SPI 2 fund under the France 2030 plan and WIND, with participation from its historical investor Capital Grand Est and new entrant NCITY, will enable Keey Aerogel to strengthen its team and implement an ambitious development plan.

“Today, our pre-industrial scale allows us to move toward full industrialisation. We plan to replicate our pilot site in France by creating three production lines, which will meet the production capacity requirements of our current clients."

We’ve validated the final stage of industrialisation for producing pure aerogels,” explained Ruiz.

Further, Keey Aerogal has gained traction with manufacturers the company collaborates with because the aerogel can be developed using existing supply chain tech for conventional aerogel manufacturing.

O’Connor shared:

"Major insulation manufacturers we’re already working with see the long-term potential. Their interest lies more in the machines they could have in the future rather than just the product we offer today. They understand the value of localized production and the cost savings it provides."

Today’s round was led by the SPI 2 fund (managed on behalf of the French state by Bpifrance under the France 2030 program) and WIND, with participation from its historical investor, Capital Grand Est, as well as a newcomer NCITY (NCI).

This project is also an exemplary model of decarbonised reindustrialisation for the Grand Est region, positioning it at the forefront of innovation and ecological transition,” notes Marc Beekenkamp, Investment Director at Capital Grand Est.

“The industrialisation of this innovative technology in France, within a circular economy framework, offers a sustainable, competitive, and environmentally friendly solution to multiple industries (construction, manufacturing, mobility, etc.) and fully aligns with the mission of the SPI Fund,” states Magali Joëssel, Head of Industrial Investments at Bpifrance.

"A matter of European sovereignty"

The startup is developing a network of local factories to address European sovereignty and energy transition challenges. This is particularly relevant in terms of the battery sector, according to O’Connor, “where there is a requirement to manufacture products within Europe for the European market. This means importing such materials from abroad is not a viable option.

“This places us in a key position, especially in the automotive sector, with our product being manufactured entirely in Europe.”

“Being able to manufacture aerogel has now become a matter of European sovereignty. Keey Aerogel combines economic independence with sustainable development. We are extremely proud to join this venture and to support such a talented and international team whose vision and ambition are transforming multiple industries, making them both more efficient and greener, ultimately contributing to building the world of tomorrow,” concludes Thierry Vandewalle, Co-Founder and Partner at WIND.

The new funds will help create new production sites, expand the Keey Aerogal team, and fuel a wide-scale expansion. The company aims to become the leading producer of silica aerogel in Europe and the world’s first manufacturer of green aerogel.

Lead image: Keey Aerogel. Photo: uncredited.

Would you like to write the first comment?

Login to post comments