French deeptech SilMach has been selected by the French Defence Procurement Agency (Commissariat des Armées) to monitor personal protective equipment such as ballistic plates inserted in bulletproof vests.

SilMach is a pioneer in silicon MEMS (Micro-Electro-Mechanical Systems), offering advanced in-house R&D, fabrication, hybrid assembly, and quality control. Their standout products include energy-free passive sensors for structural monitoring, CES-awarded micro-motors for precise actuation, and custom silicon components for high-precision applications.

Soldiers deployed in combat zones are issued essential bulletproof protection, consisting of hard ceramic and multi-layer composite plates. However, the intrinsic fragility of ceramic raises the risk of cracking in the event of an accidental fall, compromising the level of protection.

For the Armed Forces, the integration of SilMach’s technology into bulletproof protection addresses a crucial need: Real-time monitoring of protective equipment ensures traceability and reliability, boosting soldiers' confidence in their equipment.

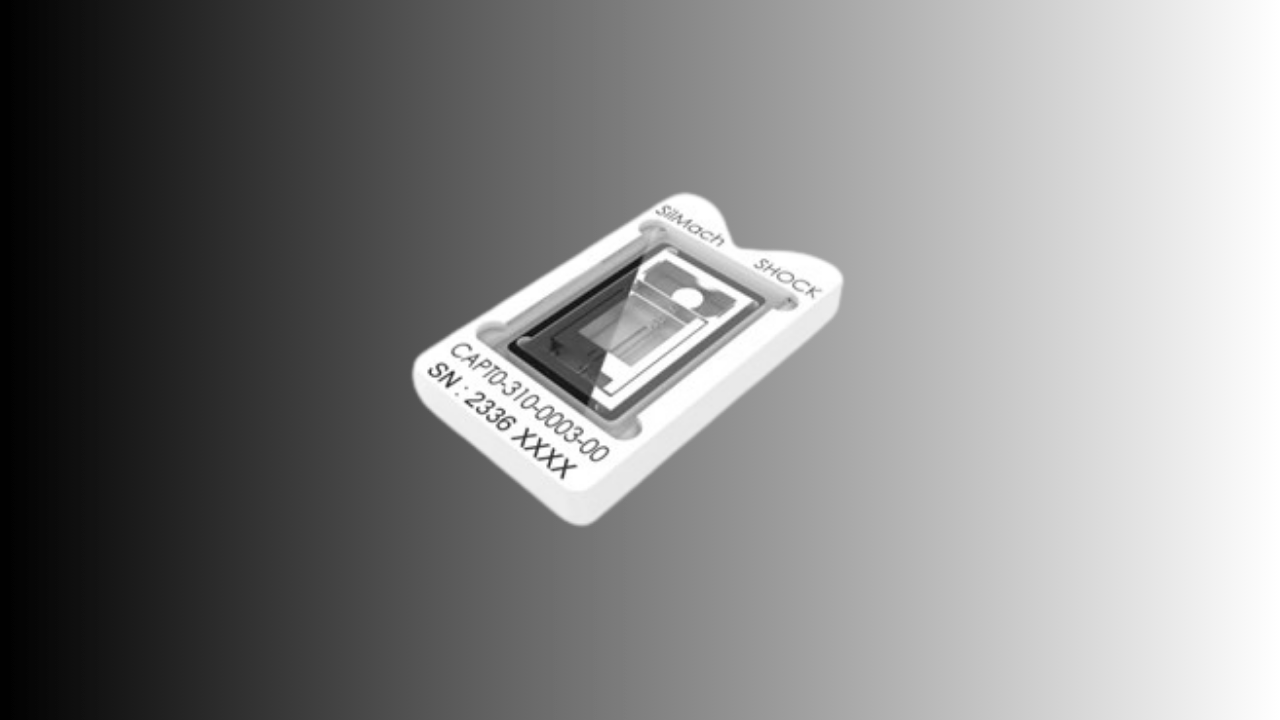

With SilMach's ChronoMEMS technology, each ballistic plate now contains an ultra-miniaturised, autonomous, energy-free sensor capable of detecting and logging the impact sustained.

Through an integrated visual indicator, armed forces can instantly check the integrity of bulletproof protection, ensuring optimum safety for soldiers and reduced maintenance costs.

The ChronoMEMS tech enables precise processing of shock and vibration data.

Among its numerous advantages:

- No need for a power source: Operates without an external power source.

- Reliable and accurate: Drift-resistant technology guarantees accurate measurement.

- Robust: Operational underwater, in space, and not affected by extreme conditions (temperature, pressure, electromagnetic fields).

- Compact and lightweight: The size and weight of a credit card chip.

- Easy tracking: Visual indicator displays information directly.

- Cost-effective: Costs just a few euros per sensor.

SilMach shall begin production this autumn, at its base in Besançon (eastern France), with the first deliveries expected in September 2025.

According to Pierre-François Louvigné, CEO of SilMach, the shock detectors installed on ballistic protection plates are designed, first and foremost, to protect our soldiers. Users can assess if a plate’s integrity has been compromised, through use or an awkward fall, at a glance.

“By making it easier to identify potentially damaged plates, we are reinforcing personnel safety and improving operational maintenance carried out by the Service du Commissariat des Armées.”

Further, the scaling of the technology’s production is already attracting interest in various sectors, including defence, security and critical infrastructures.

According to Louvigné, shock detection is a common problem affecting a wide range of fields, from aeronautics to consumer goods (helmets, smartphones, computers, etc.) and the logistics of high value-added products:

“Thanks to the expertise we have developed, with the support of the Direction Générale pour l'Armement (DGA) and the Commissariat des Armées (SCA), we are actively exploring other use cases.

Discreet, accurate and reliable, these shock detectors constantly monitor the object on which they are installed, 24 hours a day, 7 days a week. This reassures owners, manufacturers and users alike!”

Would you like to write the first comment?

Login to post comments