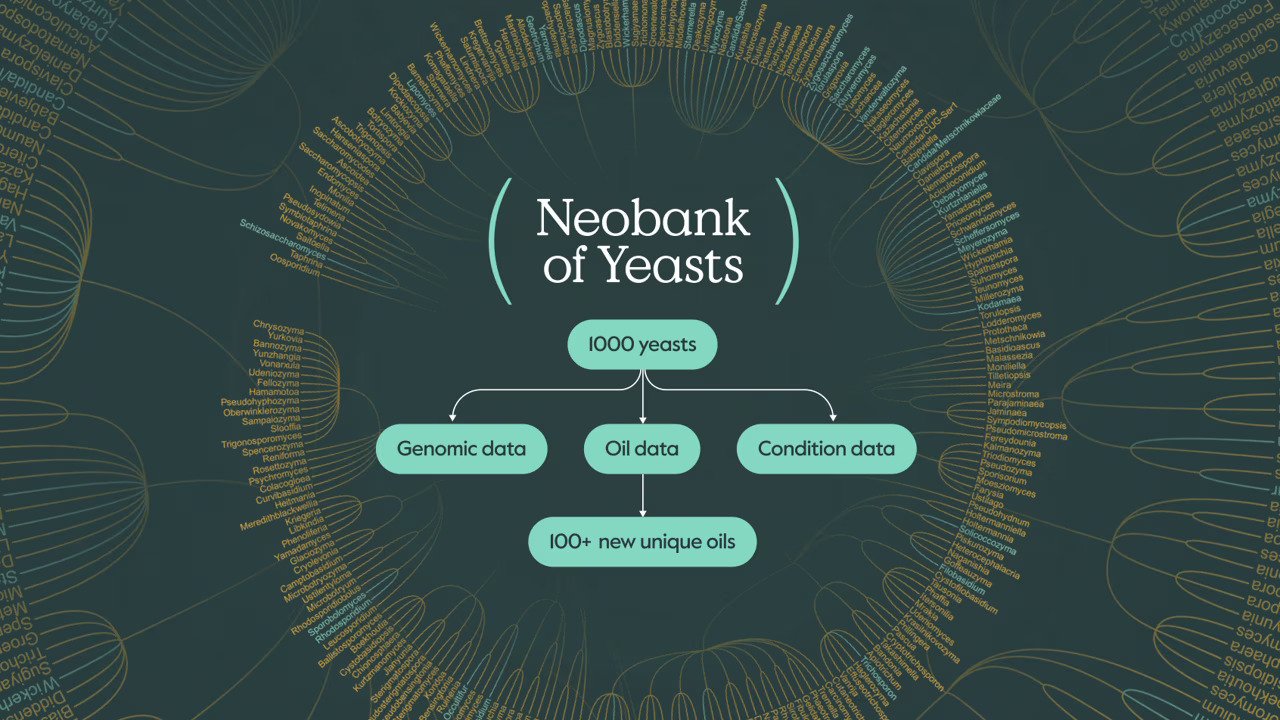

Today, SMEY, a French-German biotech company that uses fermentation and AI to create sustainable cultivated oils, announces the launch of NOY — the Neobank of Yeasts: the world’s first digital databank of yeast fatty acid profiles.

Its proprietary Neobank of Yeasts — a physical and digital library of over 1,000 strains — and its SMEY-AI platform can produce high-performance, customisable oils for food, cosmetics, and industrial applications.

I spoke to Viktor Sartakov-Korzhov, founder of SMEY to learn more-

NOY was developed after more than two years of focused R&D by a team of 30+ experts in microbial fermentation, lipid chemistry, bioinformatics, and computational biology, drawing on talent from leading institutions across Europe and the US.

SMEY’s proprietary engine

At its foundation is a curated physical library of over 1,000 yeast strains, seamlessly integrated with SMEY.AI, a proprietary system that maps genomic, metabolic, and fermentation data.

This engine identifies the optimal strains for specific product attributes, such as melting point, texture, or oxidative stability, in just hours, accelerating processes that once took weeks.

SMEY’s flagship ingredients — cHOB (Cultivated High Oleic Butter) and cCB (Cultivated Cocoa Butter) — offer stable, traceable, and non-tropical alternatives to conventional commodity oils. cHOB introduces a new category of cultivated oils offering a unique fatty acid profile with superior stability, skin feel, and sustainability.

Designed to accelerate the development of next-generation oils for consumer goods, NOY replaces years of genetic engineering with a precision-matching process: instead of modifying yeast to produce a specific oil, a process that can take up to 2 years, NOY searches its proprietary strain database to find yeast that already naturally produces the desired oil.

This cuts R&D timelines to just 30 days, allowing manufacturers to rapidly develop high-performance, fully traceable ingredient alternatives tailored to their exact specifications.

Sartakov-Korzhov explains that, unlike synthetic biology approaches, SMEY doesn’t rely on genetic modification.

“Instead, we use machine learning and adaptive laboratory evolution to optimise yeast strains — enabling the production of unique compounds while ensuring economic viability.”

How does SMEY’s platform work?

According to Sartakov-Korzhov, SMEY begins with high-throughput screenings to identify a shortlist of yeast strains with naturally high stearic acid content.

“From there, we optimise fermentation conditions and apply other proprietary techniques to fine-tune the triglyceride composition, which directly influences the cocoa butter’s melting profile and mouthfeel, critical for high-quality chocolate.”

As the process moves from discovery to production, it focuses on several key areas:

- Yield optimisation to ensure commercial viability.

- Robust, industry-relevant analytics to monitor product quality.

- Solvent-free downstream processing to meet both regulatory and sustainability standards.

“The result is a cultivated cocoa butter that not only performs like the real thing but is also economically and environmentally scalable.”

SMEY’s cultivated oils help brands meet EUDR compliance

With the European Union’s Deforestation Regulation (EUDR) coming into force, companies importing cocoa, palm oil, and shea butter must prove their supply chains are deforestation-free or risk fines of up to 4 per cent of global turnover.

Through its sustainable oil platform, SMEY helps global FMCG players stay compliant, de-risk supply chains, and outpace regulation, enabling a rapid transition to lab-grown, deforestation-free alternatives.

Produced without farmland, using minimal water, and with zero deforestation impact, SMEY’s cultivated oils enable global brands to meet clean-label and EUDR requirements while building traceable, climate-resilient supply chains.

SMEY’s vertical strategy: cultivated ingredients for the future of food and cosmetics

As SMEY advances its bioprocessing platform, the company is strategically targeting high-impact verticals where cultivated alternatives can offer both performance and sustainability — starting with food and cosmetics.

According to Sartakov-Korzhov, in the food sector, the company focuses on cultivated cocoa butter, driven by the growing impact of climate change on cocoa bean yields and the limited regions where cocoa can be harvested.

“These constraints create significant price volatility for both cocoa beans and derivatives like cocoa butter.

Meanwhile, global demand for chocolate continues to rise, fueled by population growth and untapped potential in emerging markets where per capita consumption remains low.”

Using NOY, SMEY has already produced a cultivated cocoa butter with 35 per cent stearic acid, matching the performance of traditional cocoa butter in food applications, as well as a semi-solid cultivated high-oleic butter for cosmetic use with a smooth, non-greasy texture that offers high stability and skin efficacy.

In cosmetics, the company’s focus is on exclusive, sustainable oils that offer high performance and formulation benefits.

These include oils with excellent sensory profiles, superior moisturising properties, and exceptional stability - all of which make them easy to integrate into high-end formulations.

Sartakov-Korzhov shared:

“We view shea butter and palm oil as less interesting, strategically speaking. While bioprocessing could help reduce deforestation, the current price of palm oil is too low to make it a viable target for substitution.“

Looking ahead, Sartakov-Korzhov predicts that biomanufacturing opens the door to an entirely new category of high-performance oils — ones that go beyond what traditional plant-based sources can offer.

“These oils can be designed with precise and uncommon property profiles that are critical for specific applications, including high oxidative stability, rapid absorption, a light, velvety, non-greasy skin feel, controlled melting behaviour, and enhanced nutritional value.

At the same time, they must meet additional criteria: being sustainable, free from deforestation concerns, locally produced to strengthen supply chains, and economically feasible for widespread industry adoption.”

The company is now expanding into new categories that combine technical performance with sustainability, such as:

- cHPO (Cultivated High Palmitic Oil): 90 per cent bioidentical to palm oil, and solid at room temperature, this oil is ideal for cosmetics and confectionery.

- Custom oil blends: Engineered with specific fatty acid profiles for targeted applications like SPF creams or baking fats.

- Biolubricants: Biodegradable additives designed to maintain viscosity at low temperatures.

Looking ahead, SMEY is also exploring applications in pharmaceutical excipients and engineered fats for clinical nutrition.

Sartakov-Korzhov contends:

“As demand continues to grow for climate-smart, traceable ingredients, SMEY’s cultivated fats are positioned to become foundational elements in cleaner, more resilient supply chains across sectors.”

Would you like to write the first comment?

Login to post comments